|

|||

|

|

|||

|

Page Title:

Section III - OPERATION OF EQUIPMENT |

|

||

| ||||||||||

|

|

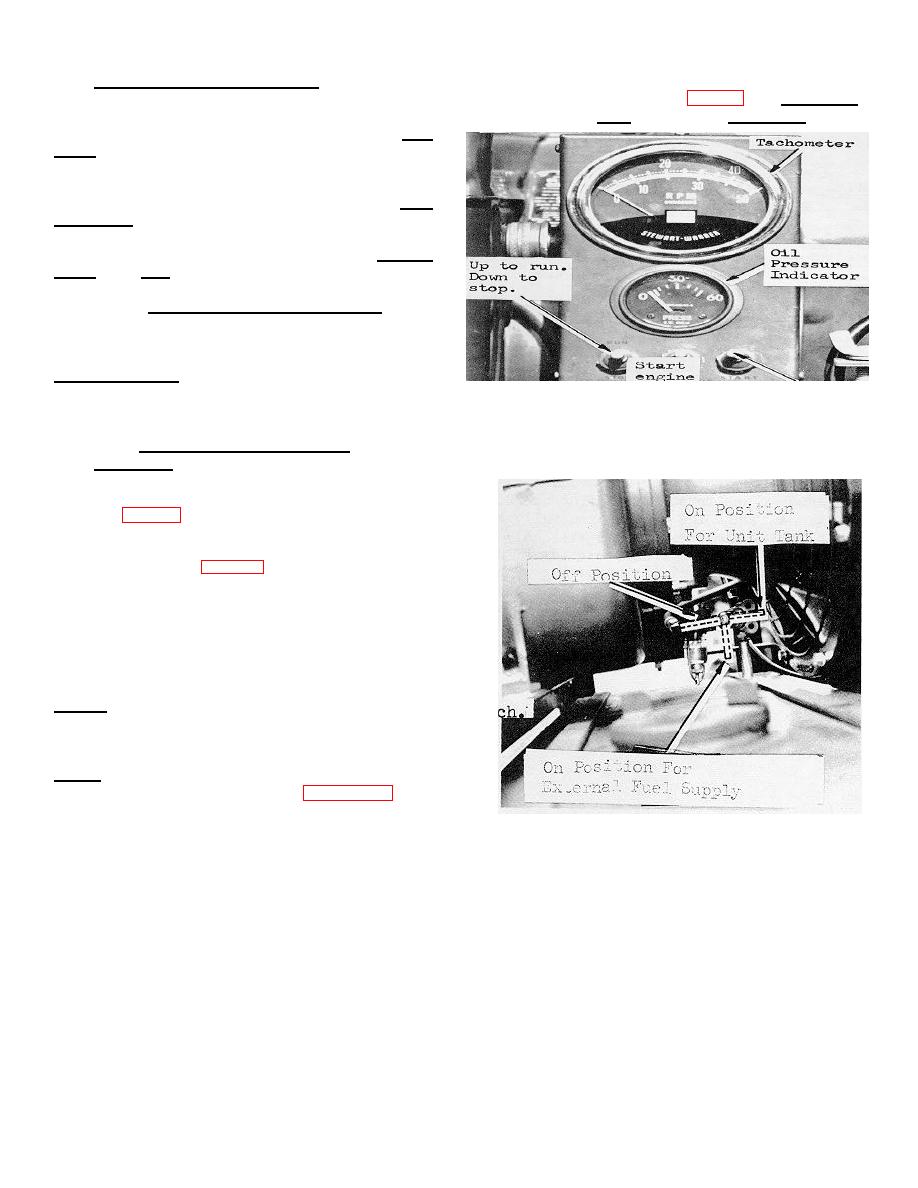

2-9. CONTROIS AND, INSTRUMETS

The controls and instruments for the pumping assembly are all contained in the control panel (fig. 2-2). The tachometer

monitors the engine speed and should normally read 3200 rpm. The oil pressure gage illustrates the oil pressure of the

engine and has a normal reading of 40-50 psi. The start

switch engages the starter when it is pressed down. The

engine is equipped with a magneto, there-fore, no

electric current is required from the battery or alternator

to energize the ignition to run the engine. With the run-

stop switch in the run position and the oil pressure

switch depressed, the magneto has a complete circuit

and can energize the ignition system. With the run-stop

switch in the stop position, the magneto is grounded and

cannot energize the ignition system. The engine is

equipped a low oil pressure shutoff switch which

performs the function of stopping the engine Of the oil

pressure falls below 20 psi and will not allow the engine

to start until it has produced 25 lbs. oil pressure. The

oil pressure switch on the control panel will override the

low oil pressure cutoff when it is depressed.

FIGURE 2-2. CONTROL PANEL

Section III - OPERATION OF EQUIPMENT

2-10. STARTING

1. Perform necessary daily preventative maintenance

services for the pumping assembly

2. Open vent on inside of fuel tank cap.

3. Move fuel shutoff to proper position for fuel source

being used (Fig. 2-3).

4. Check air cleaner inlet temperature control and oil

baffle control for proper setting (TM 5-2805-259-

14),Improper setting of inlet temperature and oil baffle

controls can cause overheating and damage to the

engine.

5. Move run-stop switch to run position.

6. Depress oil pressure switch and start switch.

NOTE: If the engine does not start after approx. 20 seconds,

release switch and allow unit to stand for a 10 minute cooling off

period. If unit does not then start, refer to TM 5-2805-259-14 to

determine cause.

NOTE: The governor has been preset to 3200 RPM, making

additional adjustment unnecessary. FIGURE 2-3 FUEL SHUT-

OFF VALVE The choke is located at the front of the engine & is

electrically operated, making manual choking unnecessary.

FIGURE 2-3. FUEL SHUT-OFF VALVE

-8-

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |