|

|||

|

|

|||

|

Page Title:

Section II - PREOPERATIVE INSTRUCTIONS |

|

||

| ||||||||||

|

|

Section II - PREOPERATIVE INSTRUCTIONS

2-6. SELECTION OF SITE

1.

Keep the unit close to water source, with a vertical suction lift of 25 feet or less.

2.

Avoid a muddy, dusty, or sandy site. If it is necessary to install the unit on soft ground, arrange a foundation

of planking, logs, or concrete.

3.

Lock the support leg in the down position.

4.

Keep the unit as level as possible.

5

Securely chock wheels to obtain maximum rigidity.

WARNING: Provide adequate ventilation or pipe the exhaust gases to the outside if operating unit in a closed area.

2-7. ATTACHMENT OF HOSE

A.

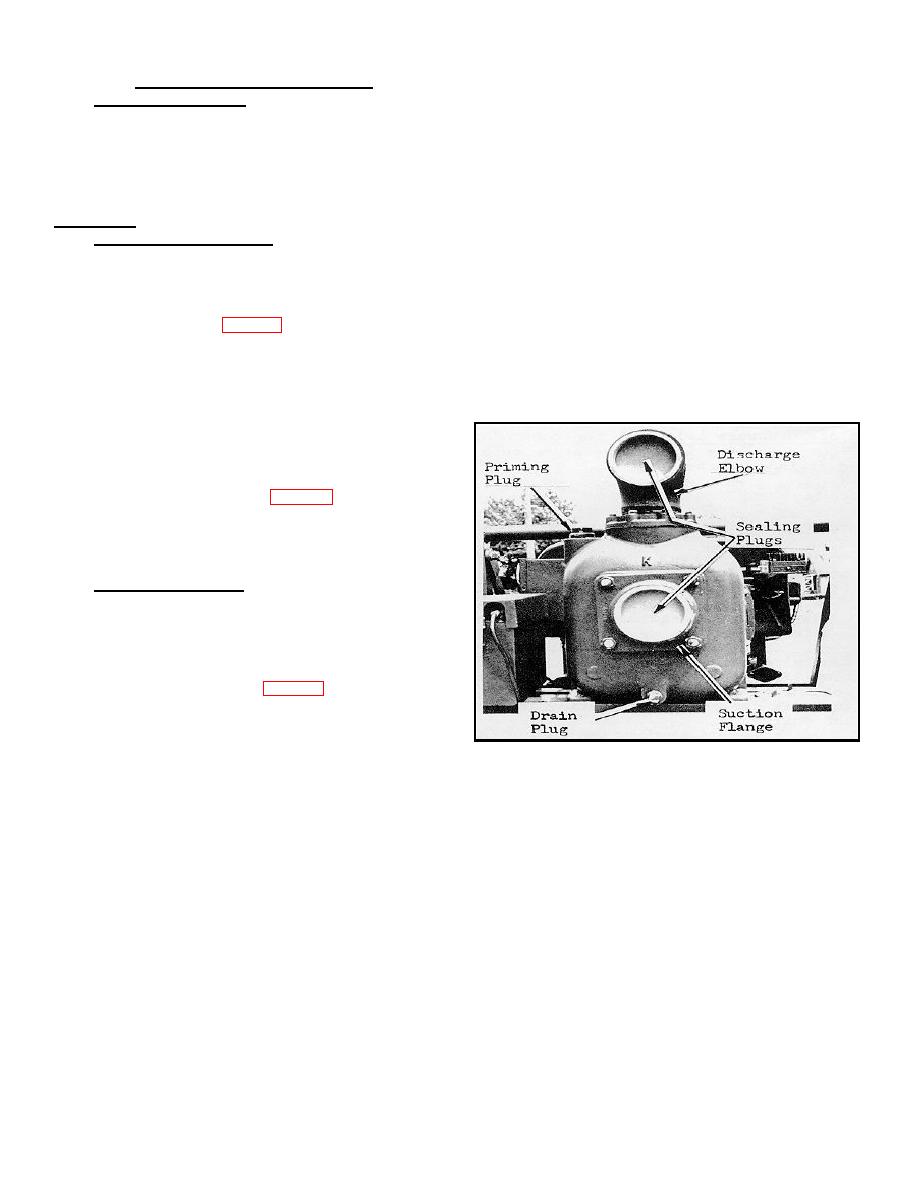

SUCTION LINIE - CAUTION: Attach a suitable strainer before operating pump. The pump inlet connection

is a 4 in. NPT. Use 4 in. reinforced noncollapsible suction hose of rigid plastic, aluminum or steel pipe. Clean all

threads and coat them with a pipe Joint compound or water-proof grease. Plastic sealing plugs are used in the suction

and discharge ports for shipping purposes, and may be saved for future use. Remove sealing plugs and insert suction

line into suction flange (fig. 2-1). All fittings and joints must be fully tightened and air tight. If suction line is not

completely air-tight, the pump will not properly complete the priming cycle and deliver water. Install suction strainer at

lower end of suction line to prevent debris and abrasive liquids from entering pump. Provide a settling bed to prevent

sand from entering pump during surf operations. Slope line downward into water course without any kinks or humps to

trap air. Submerge lower end of suction line in water source being careful to avoid any obstruction of the suction line or

vortex because of insufficient submergence.

B.

DISCHARGE LINE - The discharge connection

(both the flange and elbow) is 4" NPT. Clean all threads & coat

them with a pipe Joint compound or water-proof grease.

Remove sealing plug and insert the discharge line (4" hose or

pipe) into the discharge elbow (Fig. 2-1) and tighten securely.

Avoid kinks so as to allow free upward excape of air being

expelled during the priming cycle. Do not restrict any point of

the discharge line while the pump is in the priming cycle.

2-8. PRIMING OF PUMP - Priming must be done before

starting the engine, or the mechanical seal will be damaged or

destroyed, preventing operation of the unit. Although the pump

is generally referred to as a "self-priming" pump, it will only

prime when the pump casing has a proper internal water level.

To prime the pump, fill the casing with water after removal of

the pipe plug atop the casing (Fig. 2-1). After the casing is at

least 2/3 full replace the pipe plug and tighten completely.

FIGURE 2-1. PRIMING & ATTACHT OF HOSE

-7-

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |