|

|||

|

|

|||

|

Page Title:

CHAPTER 5. DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

D I R E C T SUPPORT AND GENERAL SUPPORT

MAINTENANCE

INSTRUCTIONS

Section I. REPAIR PARTS, SPECIAL TOOLS, AND EQUIPMENT

5-2. Maintenance Repair Parts

Repair parts and equipment are listed and

No special tools and equipment are required for the

illustrated in the repair parts and special tools list

direct support and general support maintenance of

covering direct support and general support

the reciprocating pump.

maintenance for this pump. Refer to TM 5-4320-

251-24P.

Section II. TROUBLESHOOTING

scope o f organizational maintenance and

5-3. General

operator / crew maintenance, refer to the ap-

This section describes troubles which might occur

plicable chapters of this publication.

during operation of the reciprocating pump, along

with the probable causes and corrective actions

5-4. Direct Support and General Support

relating to the troubles. Only those functions which

Maintenance Troubleshooting

are solely within scope of direct support and general

Refer to table 5-1 for troubleshooting which is

listed.

For

are

maintenance

support

allocated to the direct support and general support

troubleshooting procedures which are within the

levels of maintenance.

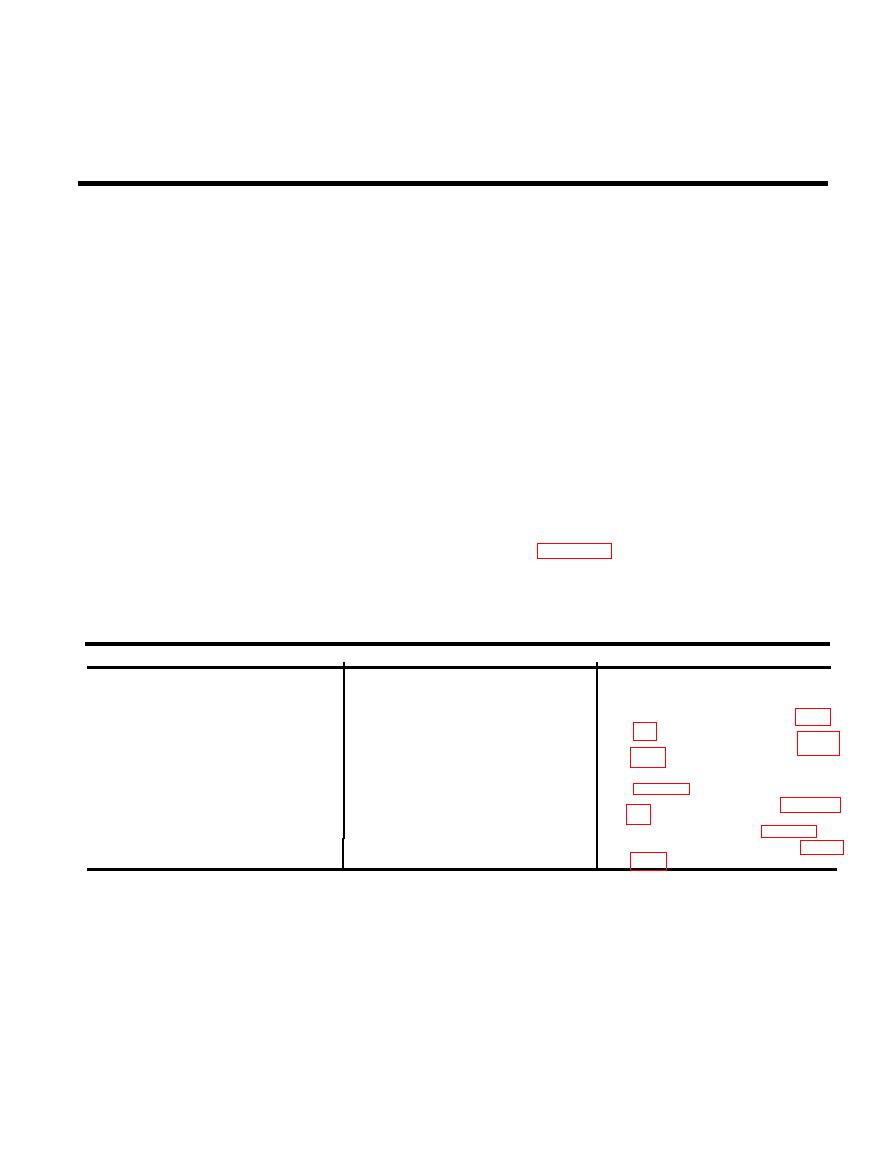

Corrective action

Probable cause

Malfunction

Replace engine.

Engine requires overhaul.

1. Engine

seised, binds or scrapes

when

turned over.

a. Defective bearing in gear case.

2. Pump

seized, binds or scrapes

when

turned over.

Defective gears or bearings.

3. Pump is noisy or vibrates ex-

(para 6-2 through 6-4).

cessively during operation.

Replace defective bearings (para 6-

Defective

bearings.

4. Pump heats up during operation.

a. Pump and engine misalined.

5. Engine labors excessively to drive

pump.

6-2 through 6-4 ).

Section III. GENERAL MAINTENANCE

5-6. Cleanliness

5-5. General

This section describes general maintenance

a. Take care to assure that the workplace is

clean before starting to disassemble the gear case.

practices which must be considered when per-

forming direct support and general support

b. Steam-clean the exterior of the gear case

maintenance on the reciprocating pump. Follow the

before starting disassembly to prevent the dirt from

entering the bearings.

instructions contained herein to help assure the

c. If compressed air is used to clean the parts,

success of the repairs or overhaul.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |