|

|||

|

|

|||

|

Page Title:

NO WATER DISCHARGE OR INSUFFICIENT DISCHARGE |

|

||

| ||||||||||

|

|

3-7. PUMP FAILS T0 START

Probable cause

Possible remedy

Possible remedy

speed should be 3600 rpm. Adjust

Probable cause

engine speed if incorrect (TM 5-

2805-259-14).

Battery weak or dead

Service battery and recharge, or

replace battery if defective (par.

Disassemble and clear obstruction

Impeller clogged

3-14).

TM 5-2805-259-14,

Refer to

Engine defective

Impeller broken, dam-

Replace impeller (par. 3-23).

Impeller frozen

Clean or replace impeller (par. 3-

aged, or worn

23).

Suction hose faulty

Replace suction hose if rubber in-

Impeller clogged or

Disassemble and clear obstruction

ner line has collapsed.

jammed

Clear strainer and suction line.

Suction line or

strainer clogged

3-8. NO WATER DISCHARGE OR INSUFFICIENT

DISCHARGE

Probable cause

Possible remedy

Possible remedy

Probable cause

Tighten or replace impeller (par.

Impeller loose, bro-

3-23) .

ken, or damaged

Remove discharge elbow at pump

Discharge check valve

pump bearing defective Replace bearing (par. 3-23).

discharge flange and clean de-

not seating

Refer to engine manual, TM 5-

Engine bearing

p o s i t s from around discharge

defective

valve. If gasket is worn in area

2805-259-14.

where check valve seats, replace

damaged gasket.

Move pump closer to water source.

Excessive suction lift

Probable cause

Possible remedy

Check all suction hose and line

Leak in suction line

connections, all exhaust primer

Tighten connections.

Suction or discharge

line connections, and exhaust

connections loose

primer valve for air-tight condi-

Tighten bolts.

Bolts on flanged joints

tion.

loos e

Exposed suction intake Submerge suction intake.

Replace gaskets (par. 3-23).

Seal defective

Make sure engine speed control is

Engine speed too low

Replace gaskets (par. 3-23).

Gaskets defective

in governed position. Check ta-

Repair or replace pump (par. 3-20

Pump body defective

chometer with pump in operation;

or 3-23).

Section IV. ELECTRICAL SYSTEM

trol panel provides controls and instruments for start-

i n g , stopping, and monitoring the operation of the

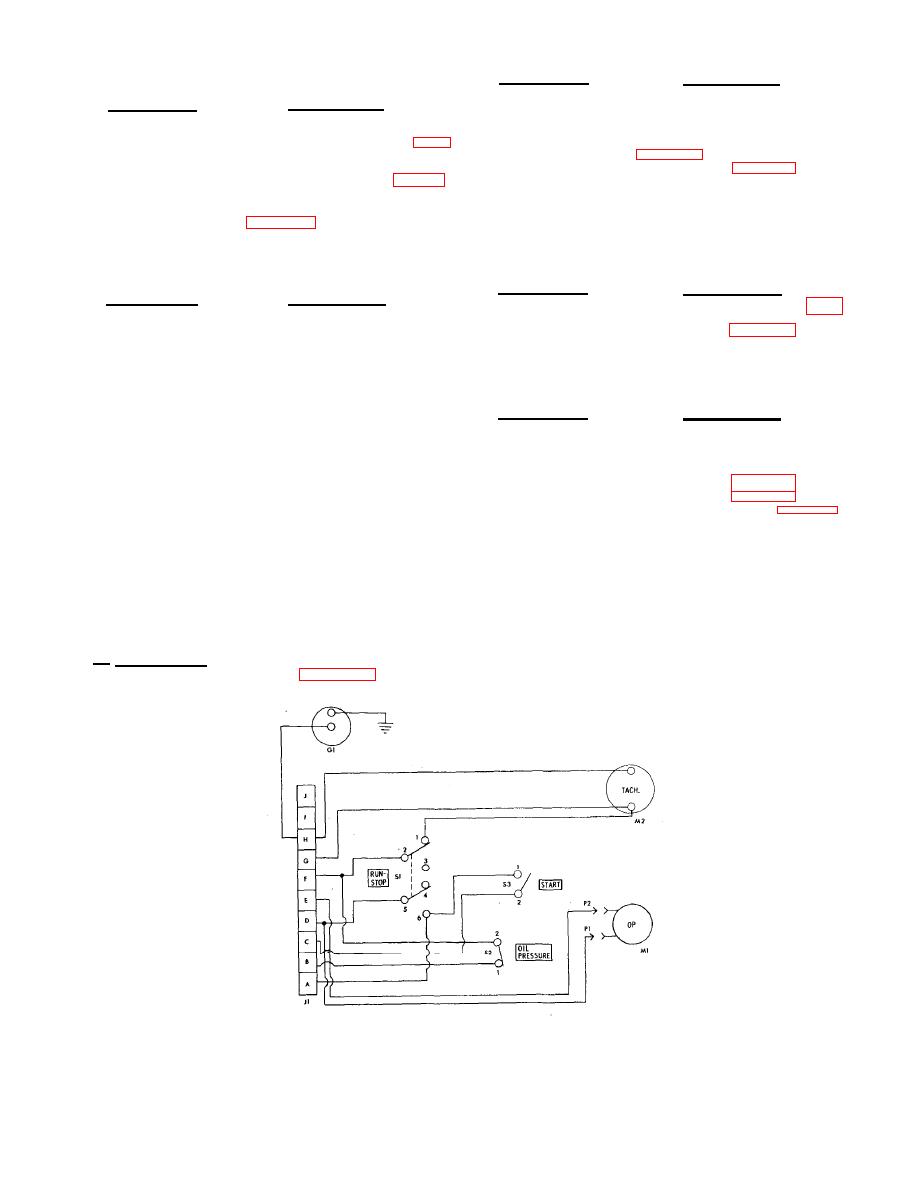

a . Control Panel. An electrical schematic diagram

e n g i n e . The RUN-STOP switch is connected to the

engine magneto, allowing it to provide spark for the

of the control panel is given in figure 3-3. The con-

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |