|

|||

|

|

|||

|

Page Title:

CHAPTER 2. INSTALLATION AND OPERATION INSTRUCTIONS |

|

||

| ||||||||||

|

|

INSTALLATION AND OPERATION INSTRUCTIONS

Section I. SERVICE UPON RECEIPT OF EQUIPMENT

c . Set the RUN-STOP switch in the STOP position

to prevent starting, and manually rotate the starting

pulley of the engine several turns to assure that the

Carefully unload the crated pump, using a lift truck

engine has not seized and that the pump impeller

or other suitable means. Take care to prevent piercing

rotates freely without scraping or binding.

crates with forks of truck.

d. Perform all daily preventive maintenance services

for the engine described in TM 5-2805-259-14.

Remove the wooden crate carefully. Do not allow

pry bars, used for crate removal, to penetrate crate

COMPONENTS

interior. This could damage pump unit.

a . The dry-charged, lead-acid storage battery is

shipped mounted in the battery box, but the electrolyte

is shipped separately. Add electrolyte to each cell

a. Inspect the pump for obvious damage which might

in the dry-charged battery until the electrolyte level

have occurred during shipment.

is above the battery plates. Do not overfill the battery.

b . Inspect for loose or missing nuts, bolts, and other

Warning. The electrolyte for the dry-charged battery

attaching hardware. Check the suction and discharge

consists of sulphuric acid. Use care when

ports for damaged threads.

Note. The pump has been tested prior to shipment.

Since gaskets have a tendency to dry and

shrink after testing, make especially sure

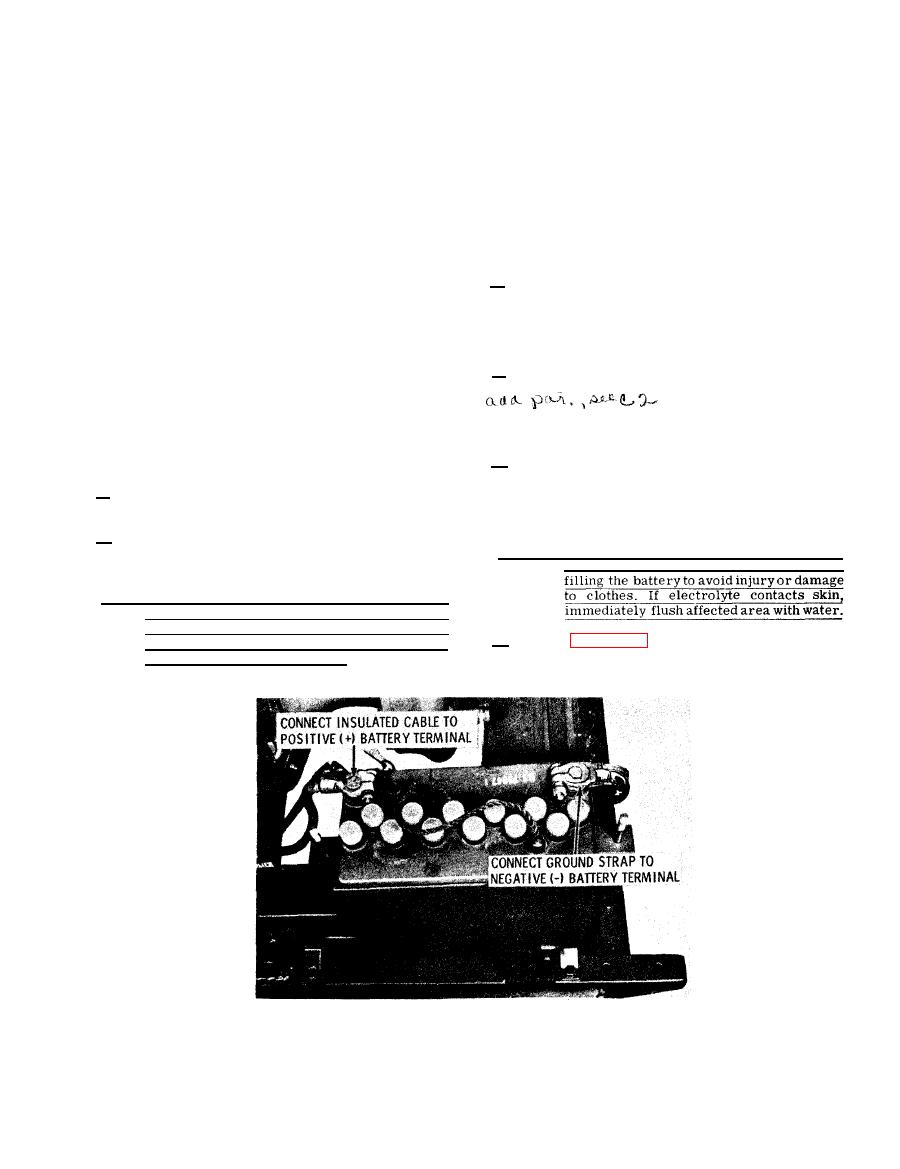

b . Refer to figure 2-1 and connect battery cables;

that all bolts on gasket joints are tight in

replace cover.

order to prevent pump leakage.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |