|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

b. Removal.

to the valve face. This should show a contact width of

1/32 to 3/64 inch, and should fall well within the width of

the valve face, leaving at least 1/64 inch on either side

(1) Refer to paragraph 5-22a and remove the

of the contact area. If the contact area is greater than

engine and housing from the pumping unit.

1/16 inch, narrow the contact area by grinding the

outside diameter of the seat with a 15 degree stone, or

by grinding the inside diameter of the seat with a 60

degree or 75 degree stone. After the seat area is

corrected, touch the seat lightly with the original grinding

stone to remove the burred or feathered edge.

(11) Inspect the spring retainer seats, spring

retainer locks, valve stem caps, and valve tappet

assemblies for cracks, scoring, overheating, and wear.

Replace damaged parts.

valves in cylinder head.

install cylinder head in reverse order.

6-14. Oil Pan

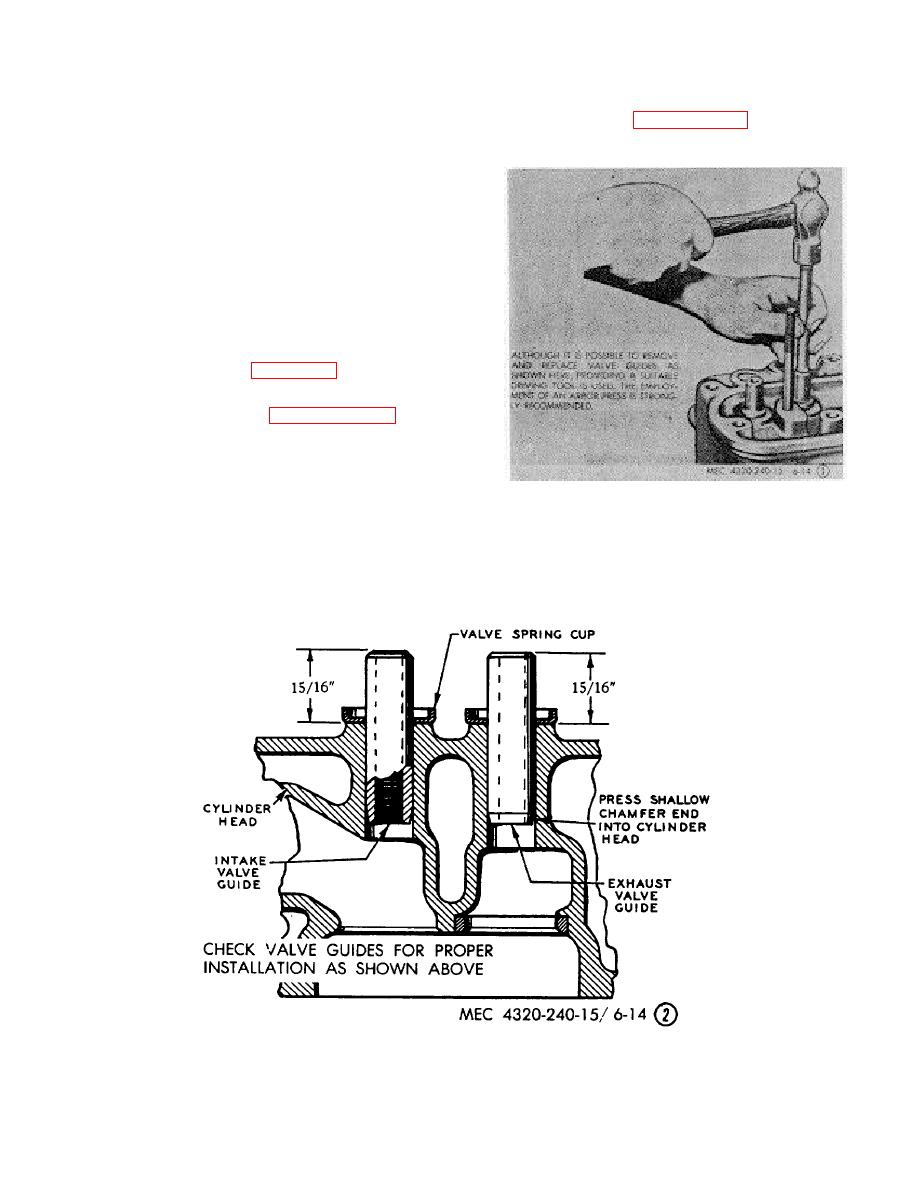

Figure 6-14. (1)Installing valve guide.

a. General. The oil pan is located at the lower end of

the cylinder block. It serves as a container for the oil

which is circulated through the engine. It also aids in

the cooling of the hot oil.

Figure 6-14. (2)- Continued.

6-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |