|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

mounted on the control panel which is located on the

b Removal and Disassembly.

pumping assemblies. Refer to figure 1-4 for the wiring

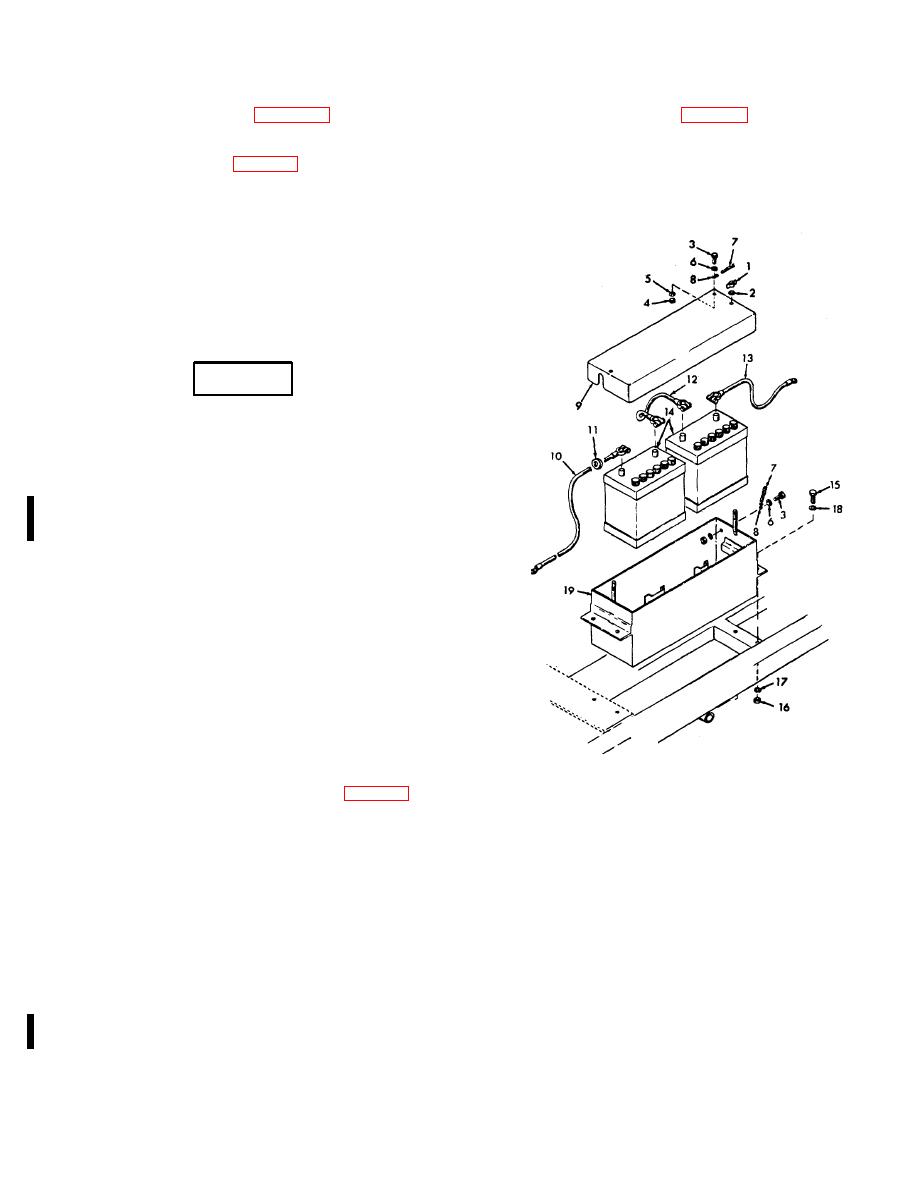

(1) Remove the wing nut (1, fig. 4-24) and flat washer

diagram showing the electrical connections between the

(2), and remove the battery box cover (9). If any of the

engine and controls. The function of the controls and

parts are damaged, remove the cap screws (3), nuts (4),

lock washers (5), and flat washers (6), and remove the

instruments is described in table 2-1

chain (7) and S-hooks (8).

g. The starter switch, mounted on the control panel,

closes the circuit to energize the starting motor. When

the push-button is released, the starting motor

deenergizes.

h. The ignition switch, mounted on the control

panel, grounds the magneto and stops the engine. This

switch is in the same circuit as the oil pressure safety

switch.

4-37. Batteries and Cables

a. Service. To charge batteries, proceed as

follows:

WARNING

Do not smoke or use an open name in

the vicinity when servicing the

batteries. Batteries generate hydrogen

gas, which is highly explosive.

(1) Remove caps and check the electrolyte

level in each cell. If any are low, fill to proper level with

distilled water or good grade drinking water (excluding

mineral water).

(2) Start engine and allow it to run for 10 to 15

minutes. Stop the engine and check the batteries with a

hydrometer.

Fully charged batteries shall have a

minimum specific gravity of 1.275 at 75 F.

CAUTION

Constant-current battery charging is

always preferred. If you must use a

constant-potential

charger,

battery

temperatures must be maintained at

less than 130 F by interrupting the

charging procedure as this temperature

is approached.

(3) If the specific gravity of the electrolyte is

1.

Wing nut

11.

Insulating grommet

less than 1.250, the batteries must be charged before

2.

Flat washer

12.

Jumper cable

use. A battery-charging receptacle (5, fig. 3-2) is

provided at the lower left rear of the engine housing.

3.

Cap screw

13.

Ground cable

Connect the charger into this receptacle. When you

4.

Nut

14.

Battery

charge the batteries, use a constant current charger.

5.

Lock washer

15.

Cap screw

Check the specific gravity of the electrolyte every 30

6.

Flat washer

16.

Nut

minutes. The batteries are fully charged when you get a

7.

Chain

17.

Lock washer

constant specific gravity reading for three 30-minute

8.

5-hook

18.

Lock washer

intervals.

9.

Battery box cover

19.

Battery box

(4) During charging, check the electrolyte level

10.

Battery cable

frequently. Add distilled water when necessary to

maintain the battery electrolyte level. Continue charging

Figure 4-24. Batteries, battery box, and cables,

after adding water to ensure proper mixing of the

exploded view.

solution.

NOTE

Military batteries and maintenance free

batteries cannot be mixed.

(5) Charge the battery a minimum of once each month

when the battery is not in service. If the battery fails to

take or maintain a charge, replace it.

Change 1

4-40

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |