|

|||

|

|

|||

|

Page Title:

Section II. PREVENTIVE MAINTENANCE CHECKS AND SERVICES |

|

||

| ||||||||||

|

|

CAUTION

Do not use solvent of any kind to

clean the oil filter housing. If solvent

gets into the lubricating system, it

can thin the oil so that it no longer

protects the engine from wear.

(4) Wipe the interior of the filter housing with a

clean, dry cloth.

(5) Install a new filter element in the filter

housing.

(6) Replace gasket and cap. Before you tighten

the attaching screw, carefully check the position of the

gasket. If the cap is slightly tilted, the gasket probably is

not seated. Loosen the screw and recheck it. When

you are sure that the gasket is in its correct position,

tighten the screw on the cover. It is not necessary to

tighten the screw with all your strength, but it must be

tight enough so that it will not loosen up during

operation.

(7) Add 51/2 quarts of the proper grade oil (see

housing and filler tube.

(8) Start engine and watch the oil filter closely.

If the gasket is not properly seated, a large amount of oil

can be lost in a very short time. No leakage is

permitted. If you see any leakage, stop the engine

immediately and repeat step (6) above to stop the leak.

(9) Shut off the engine after 3 to 5 minutes.

Wait 5 to 10 minutes for the engine oil to drain back into

the crankcase, and check the oil level on the dipstick (8,

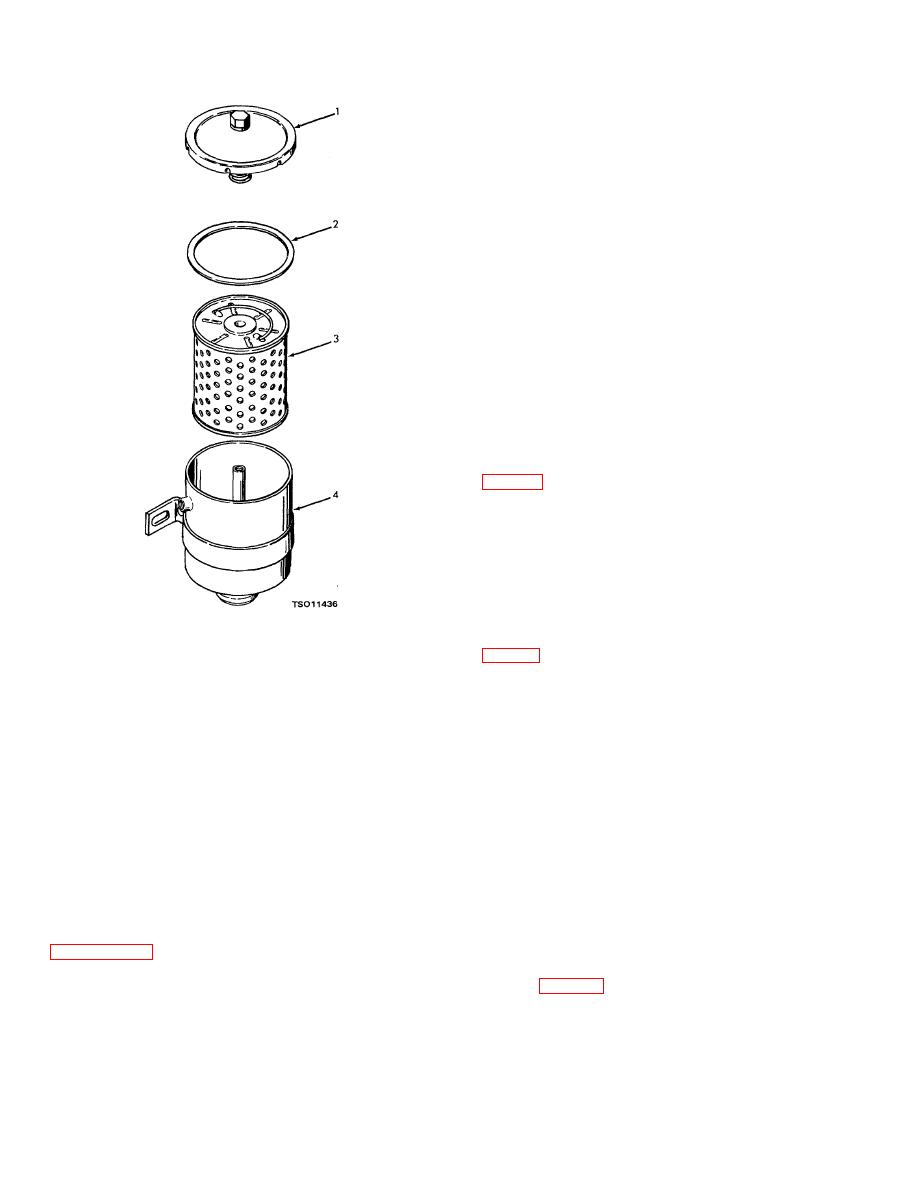

1. Oil filter cover

3. Filter element

2. Cover gasket

4. Oil filter housing

3-4. Pump Lubrication

Figure 3-4. Oil filter, exploded view.

The pump shaft bearings were packed with grease by

the manufacturer at assembly and require no

(3) Remove the oil filter element (3) by lifting up

subsequent lubrication except at overhaul periods. No

the handle provided. Use a clean cloth to remove

other pump lubrication is required.

excess oil from the filter housing (4).

Section II. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

3-5. General

ceased. Stop operation immediately if a deficiency is

noted during operation which would damage the

equipment if operation were continued. All deficiencies

To ensure that the centrifugal pump is ready for

and shortcomings will be recorded together with the

operation at all times, it must be inspected

corrective action taken on DA Form 2404 (Equipment

systematically so that defects may be discovered and

Inspection and Maintenance Worksheet) at the earliest

corrected before they result in serious damage or

possible opportunity.

failure. The necessary preventive maintenance checks

and services to be performed are listed and described in

3-6. Preventive Maintenance Checks and Services

sequence of minimum inspection requirements. Defects

discovered during operation of the unit will be noted for

Refer to table 3-1 for a listing of operator's preventive

future correction to be made as soon as operation has

maintenance checks and services.

3-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |