|

| |

APPENDIX A

FIG. 10. REMOVING ROTOR COVER, TOP OF SCREW-

DRIVER IS PLACED IN SLOT AND PRIED

UPWARD TO PREVENT DAMAGE TO TOP EDGE

OF ROTOR.

to remove scale, etc., after which all parts should be

thoroughly washed in solvent or kerosene. The Blade

Rollers or bearings must revolve freely on their shafts

without excessive looseness. If the Blade Rollers

(bearings) are worn, they must be replaced. Blade

Roller or bearing replacement is not normally attempted

in the field but can be accomplished with proper

equipment and care.

If any burrs are apparent on the blades, they should be

removed. Sharp, clean cut edges should be maintained

on the blades. Blade blocks should be flat and clean, if

grooved they maybe turned over and used on the

opposite side, otherwise they should be replaced. If the

Rotor is equipped with rotor cover rollers and pins, these

should also be replaced if they show wear or roughness.

Reassemble in reverse order from disassembly, being

sure that al I bearing locks are properly positioned.

The jackshaft extends through a replaceable cartridge

type Packing Gland in the single case meters. Remove

Jack Shaft Pinion and draw the Shaft from the Gland. If

the Jack shaft is worn or corroded, it should be replaced,

otherwise it may be cleaned and polished with a fine

crocus cloth. Polish with a rotary motion so as not to cut

vertical grooves or scratches in the Shaft. Coat the

Shaft with light grease before inserting in the gland. If

the Packing Gland is worn, replace with a new Gland

cartridge and gasket. Check Jack Shaft Bushing and

replace if worn.

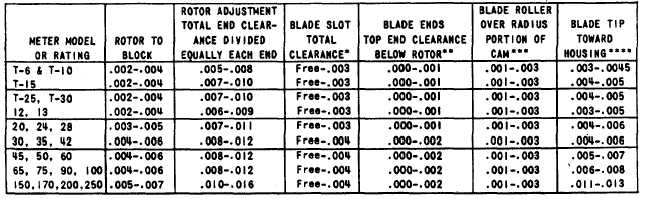

TABLE 1 - CLEARANCE GUIDE

THIS CLEARANCE GUIDE LISTS THE RECOMMENDED MINIMUM AND MAXIMUM FITTING CLEARANCES FOR NEW AND REPAIRED

METERS. CLEARANCES MAY EXCEED THE MAXIMUM SHOWN PROVIDED THE METER PROVES WITHIN ACCEPTABLE ACCURACY.

THE ABOVE CLEARANCES APPLY ONLY TO METERS OPERATING AT

STANDARD OPERATING TEMPERATURES OF 20

TO 150°F. AND

VISCOSITIES LESS THAN 5,000 SSU. FOR HIGHER TEMPERATURES

AND VISCOSITIES CONSULT FACTORY.

*BLADES SHOULD MOVE FREELY IN ROTOR SLOTS AND THE

AVERAGE CLEARANCE IN EACH SLOT SHOULD NOT EXCEED THE

LISTED CLEARANCES. NOR SHOULD ANY SINGLE POINT BE MORE

THAN 50% ABOVE THE MAXIMUM LISTED.

**THE BLADE SHOULD BE SHORTER THAN THE ROTOR BY THE

AMOUNT SPECIFIED TO ALLOW FOR DIFFERENCE IN COEFFICIENT

OF EXPANSION BETWEEN THE ALUMINUM BLADES AND IRON

ROTOR. (LOWER EDGE OF BLADE SHOULD NOT PROJECT

BELOW BOTTOM SURFACE OF ROTOR.)

***WITH THE BLADE IN THE MEASURING CHAMBER. THIS

TOTAL CLEARANCE SHOULD BE MAINTAINED BETWEEN THE

RADIUS OF THE CAM AND ONE ROLLER ONLY.

****WITH THE BLADE HELD TOWARD (AWAY ON T-6 AND T-10)

THE HOUSING, THESE CLEARANCES SHOULD BE MAINTAINED

BETWEEN THE MEASURING CHAMBER AND THE FULL LENGTH

OF THE EDGE OF THE BLADE.

A9-23

|