|

| |

APPENDIX A

Clearances should be checked with a leaf type feeler

gage. Any average of clearances that are outside of the

tolerance should be noted with a view toward replacing

the worn parts. It is well to call attention to the fact that

although certain parts may be at or over the borderline

of the maximum allowable tolerance, consideration

should be given to the condition of the part and the

accuracies being obtained in calibrating the meter. By

this it is meant that certain major parts such as the rotor

and blades need not be replaced if no difficulty is

experienced in proving the meter and records show that

there is no appreciable change in accuracy from one

meter proving to another.

With the rotor assembly still in the meter housing, blade

roller and/or cam clearances can be checked by moving

the blades back and forth against the cam. Each blade

should be checked in two positions, one position at right

angles to the first position. This determination can

usually be made visually.

It is recommended that a support be used to

disassemble the rotor. A simple and inexpensive work

plate can be fabricated from pipe and steel plate.

Before attempting further disassembling, turn the rotor

and shaft assembly upside down on the support plate.

On the T-15 Meter, drive out the pin that holds the shaft

key and remove the key. The S13 sump plate is

fastened to the shaft with Allen head set screws, 90

degrees apart, with two set screws at each location. Be

sure to remove the first one completely, 'then loosen the

other screws that hold the rotor cover to the rotor and

carefully pry off the Rotor Cover. This should be done

in such a manner so as not to damage the edge of the

rotor. ( See Figure 10.) Remove the lower bearing and

bearing cover from the shaft. Mark position of blades

using a punch or file with relation to rotor slots. This will

permit replacement in their respective slots and in the

same positions.

Next, carefully lift out the lower blade and then withdraw

the shaft. The upper blade can then be removed. Turn

the Rotor over and remove the Rotor Gear Plate,

making the Upper Radial Bearing and the Thrust

Bearing accessible. Clean all parts thoroughly. Fine

emery cloth may be used to remove scale, etc., after

A9-22

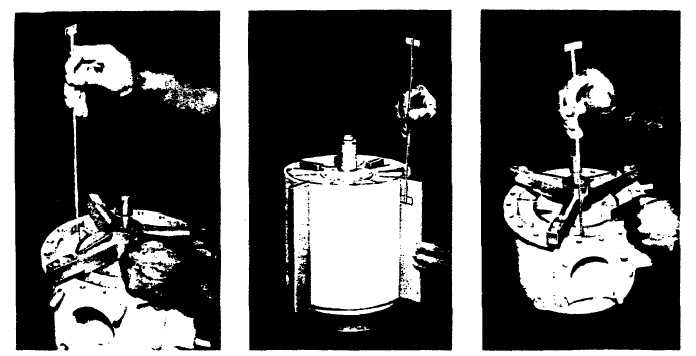

FIG. 7.

USING FEELER GAUGE TO

CHECK BLADE TO HOU-

SING CLEARANCES.

FIG. 8.

CHECKING BLADE SLOT

CLEARNCE WITH FEELER

GAUGE. CLEARANCES

MAY BE CHECKED WITH

BLADES POSITIONED IN-

SIDE OF OR OUTSIDE OF

ROTOR,

BUT

ROTOR

COVER MUST BE ON.

FIG. 9.

CHECKING CLEARANCES

BETWEEN

ROTOR

AND

BLOCK.

|