|

|||

|

|

|||

|

Page Title:

Section II. OPERATOR/CREW MAINTENANCE |

|

||

| ||||||||||

|

|

TM 10-7200-200-13

Section Il. OPERATOR/CREW MAINTENANCE

3-3. Lubrication Instructions

(2) Inspect the interior of each can for cleanliness

and for the presence of contamination and rust. Rust

The five gallon water can does not require lubrica-

other than pin point rust is not permissible and

tion.

repainting the interior is prohibited.

(3) Inspect the exterior of each can for the

3-4. Preventive Maintenance Services

condition of the paint.

The necessary preventive maintenance checks and

b. Cleaning.

services to be performed at regularly scheduled

(1) Wash dirt, dust, grease, and other foreign

intervals are listed in table 3-1.

matter from the exterior of the cans with hot water,

soap, and brush.

3-5. Cleaning and Inspection

(2) Clean the interior of the can by immersing in

a. Inspection

hot water containing a hand-dishwashing com-

(1) Inspect the can for leaks, dents, holes, and

pound, P-D410, and swishing until thoroughly clean.

other damage. Make sure the can is free from leaks.

Do not scour with steel wool.

Check dented condition of can. Check the condition of

(3) Rinse cans in clean boiling water, turn upside

the flange on each can.

down, and allow to dry.

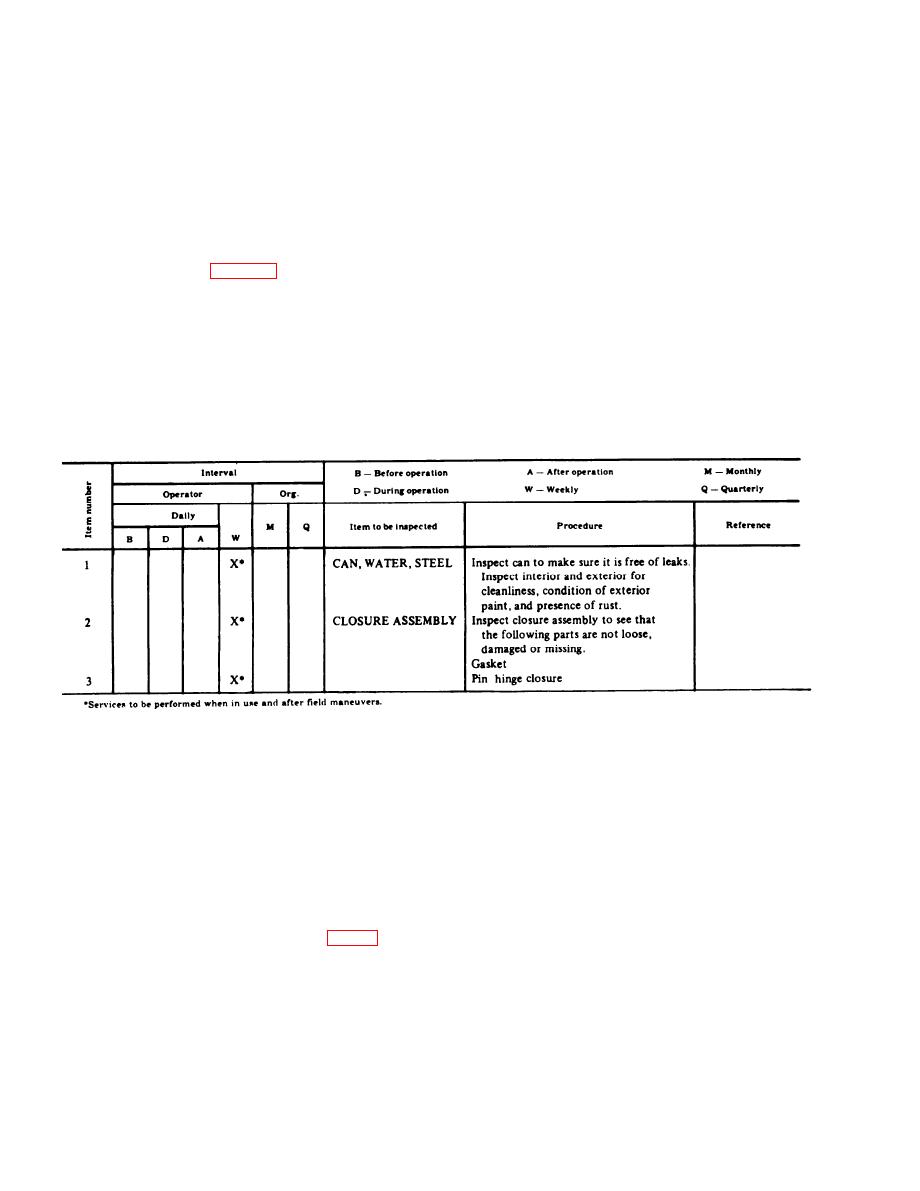

Table 3-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

Section III. ORGANIZATIONAL MAINTENANCE

3-6. Special Tools and Equipment

(1) Lift locking lever cam (2) and open cover of

can.

The five gallon water can does not require special

(2) File off peened end of hinge pin (3) securing

tools, parts, or equipment.

closure assembly (5) to the hinge brackets.

3-7. Repair.

(3) Remove hinge pin (3) and washer (4). Replace

with new closure assembly.

a. Nonmetallic Washer (Gasket). Re-cement loose

(4) Replace pin and washer with new ones. Use a

washers that are in good condition. Replace missing

hammer to peen replacement hinge pin while

or defective washers with new ones (1, fig. 3-l). Use

holding opposite end of pin in position with another

only approved nontoxic cement (FSN 8040-273-8717).

hammer or suitable tool.

b. Closure Assembly. Replace the closure assembly

when damaged.

Change 1

3-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |