|

| |

TM 10-4930-250-13&P

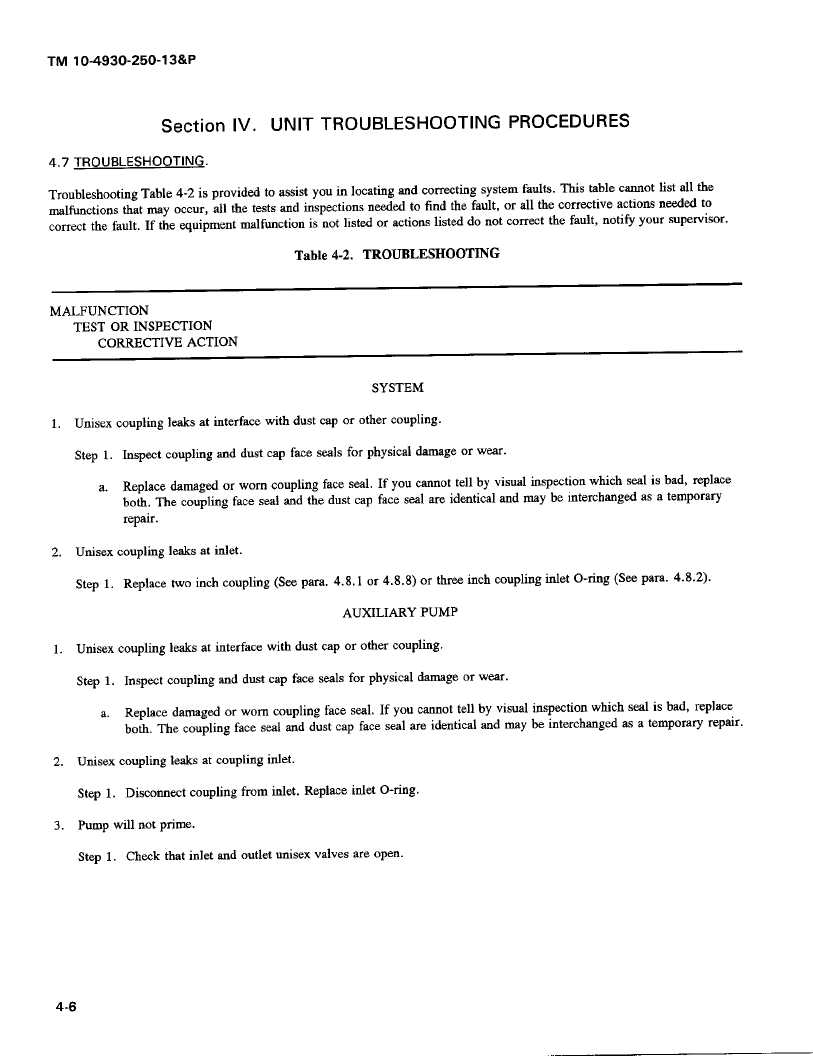

Section IV. UNIT TROUBLESHOOTINGPROCEDURES

4.7 TROUBLESHOOTING.

Troubleshooting Table 4-2 is provided to assist you in locating and correcting system faults. This table cannot list all the

malfunctions that may occur, all the tests and inspections needed to find the fault, or all the coffective actions needed to

correct the fault. If the equipment malfunction is not listed or actions listed do not correct the fault, notify your supervisor.

Table 4-2. TROUBLESHOOTING

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

SYSTEM

1. Unisex coupling leaks at interface with dust cap or other coupling.

Step 1. Inspect coupling and dust cap face seals for physical damage or wear.

a. Replace damaged or worn coupling face seal. If you cannot tell by visual inspection which seal is bad, replace

both. ne coupling face seal and the dust cap face seal are identical and may be interchanged as a temporary

repair.

2. Unisex coupling leaks at inlet.

Step 1. Replace two inch coupling (See para. 4.8.1 or 4.8.8) or three inch coupling inlet O-ring (See para. 4.8.2).

AUXILIARY PUMP

1 .

Unisex coupling leaks at interface with dust cap or other coupling.

Step 1. Inspect coupling and dust cap face seals for physical damage or wear.

a. Replace damaged or worn coupling face seal. If you cannot tell by visual inspection which seal is bad, replace

both. The coupling face seal and dust cap face seal are identical and may be interchanged as a temporary repair.

2. Unisex coupling leaks at coupling inlet.

Step 1. Disconnect coupling from inlet. Replace inlet O-ring.

3. Pump will not prime.

Step 1. Check that inlet and outlet unisex valves are open.

4-6

|