|

| |

T M 1 0 - 3 8 3 5 - 2 1 9 - 14

I n t e r v a l

Item

No.

3

4

Table 2-1. Preventive Maintenance Checks and Services (PMCS) (cent).

B - Before Operation

D - During Operation

B

D

A

Item to be inspected

P r o c e d u re

Hoseline Assembly

a.

b .

c.

d .

N O T E

Hoseline cannot be inspected until

removed from flaking box.

Inspect hoseline for security of all

coupling clamps and rings. Check for

damaged couplings, rings or

defective gaskets. Replace damaged

parts.

Check entire length of hoseline for

any breaks, leaks or seepage through

hose wall. Repair hose by using

repair kit if defects noted.

Check entire length of hoseline for

rubbing or chafing against trees,

rocks, suspension towers or any

objects which might damage hose-

Iine. Reposition as required.

Check for security of all suspension

devices if used.

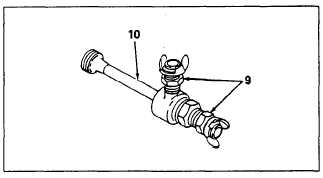

Ejector Jet Assembly

Inspect couplings and adapter (9) and

body (10) for cracks, plugged ports and

thread damage. If damage is found,

notify higher level of maintenance

A - After Operation

Equipment is not

ready/available if:

Loose or damaged clamps,

rings or gaskets.

Walls are excessively worn

or hose contains breaks.

Any sign of leakage.

Jet assembly is cracked,

ports plugged, or threads

d a m a g e d.

2 -6

|