|

|||

|

|

|||

|

Page Title:

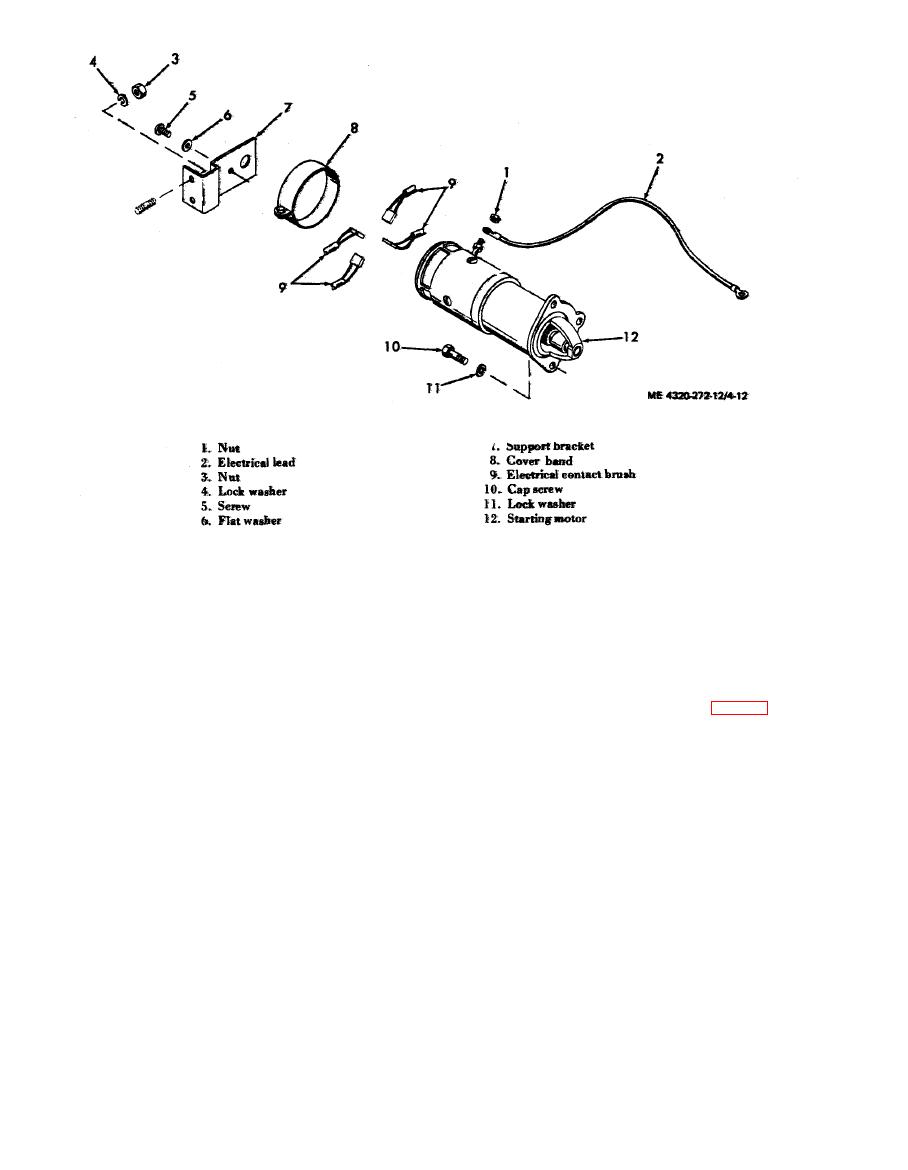

Figure 4-12. Starting motor and brush replacement, exploded view. |

|

||

| ||||||||||

|

|

(4) Remove the brush cover band (8, fig. 4 -

(2) Remove the nuts (3) and lock washers (4)

12) and inspect the starting motor brushes; replace

that secure the support bracket (7) to the engine

if necessary (subparagraph c below).

block.

(5) Replace with a new starting motor if the

(3) Remove the screw (5) and flat washer (6)

old motor is damaged in any way.

that mount the support bracket (7) to the starting

c. Starter Brush Replacement. If inspection

motor; remove the support bracket.

shows you that the brushes are worn less than 3/8

(4) Remove the three cap screws (10) and

inch, replace them as follows:

lock washers (11) that secure the starting motor

(1) Disconnect the electrical lead (2, fig. 4-12)

(12) to the flywheel housing. Pull straight out on

to the starting motor from the starter switch.

the starting motor to remove it from the engine.

(2) Loosen the cover band screw and slide the

b. Cleaning and Inspection.

cover band (8) from over the brush access openings

WARNING

in the starter frame.

Clean all parts in a well-ventilated area.

(3) Unhook the spring retaining each brush

Avoid inhalation of solvent fumes and

and hold it out of the way of the brush. Holding the

p r o l o n g e d exposure of the skin to

cleaning solvent. W a s h exposed skin

brush by the leads, carefully remove brush through

access opening. Remove brush only far enough to

thoroughly.

disconnect brush leads from field leads. Repeat this

(1) Clean the exterior of the starting motor

procedure with each brush.

with a cloth dampened with cleaning solvent (fed.

spec. P-D-680). When you use solvent, take care to

NOTE

prevent it from entering the starting motor.

Before you install the new brushes, check the

(2) Inspect the starting motor for cracks, signs

commutator on the armature shaft. It must be

of overheating, and other damage.

smooth and concentric, free from burrs, scoring, high

(3) Inspect the starting motor drive for worn,

segments, or other damage. Replace the starting

chipped, and broken gear teeth, and other broken

motor if the commutator is damaged.

parts.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |