|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

faulty ignition timing. You should recheck as

cracks, and other damage. If it is necessary to reuse

directed above.

the plugs, correct the contact gap to 0.030 inch.

(8) With the engine running at 140050

(5) Replace any spark plugs whose condition

rpm, you can check for proper spark advance with

is doubtful.

a timing light. The proper spark advance is in-

c. Installation.

dicated on the shroud by a 1/8 inch hole 230 before

(1) Make sure all spark plugs are gapped to

the vertical centerline on the number 1 and 3

0.030 inch before you install them.

cylinders. For easier recognition of the X-marked

(2) Install the spark plugs, using a torque

vane, you should whiten it with chalk or paint.

wrench. Tighten the spark plugs to 25 to 30 foot-

Connect the timing light to the number 1 spark

pounds torque.

plug and check that the indication on the flywheel

(3) Install the shielded spark plug cables on

is alined with the spark advance mark on the

the spark plugs. Make sure the leads are not in-

shroud. If it is not exactly alined, you can rotate

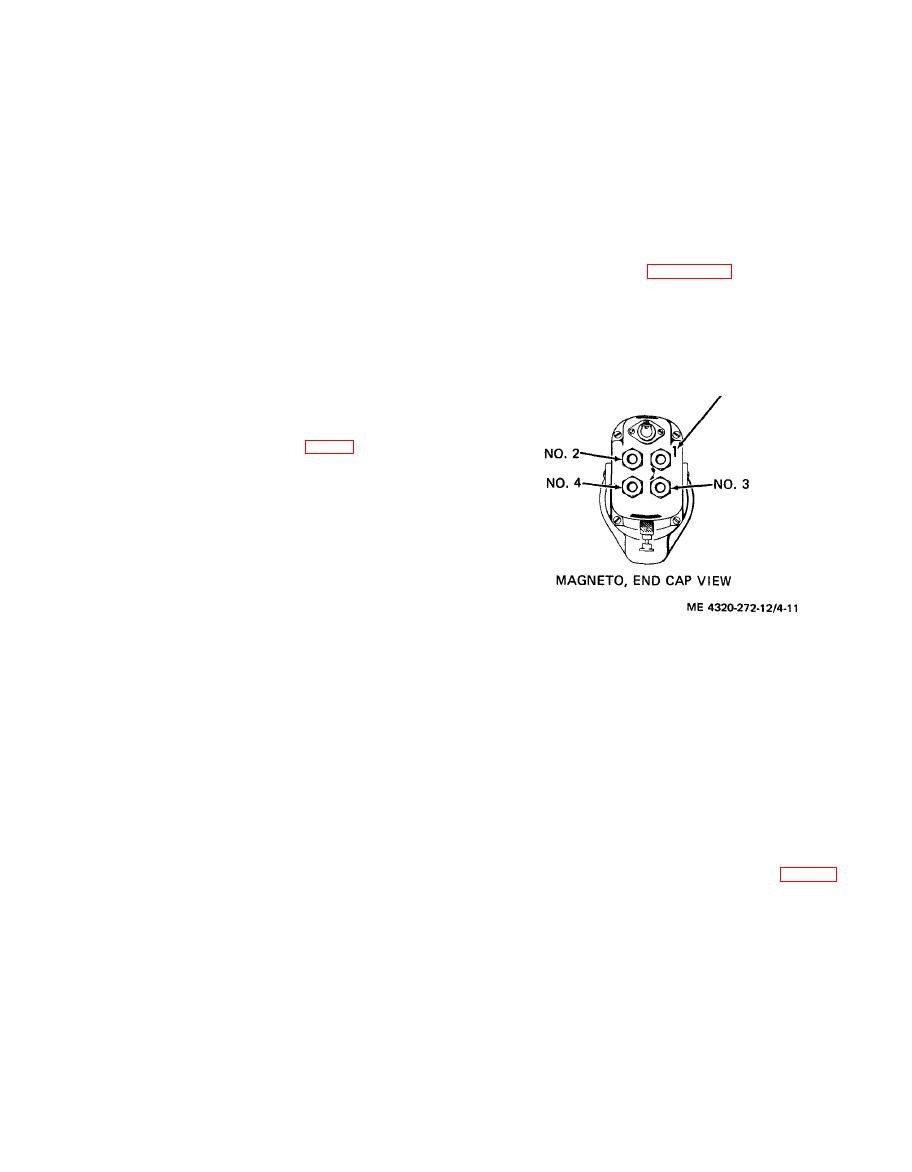

terchanged. Refer to figure 4-11 to assure proper

the magneto slightly until the correct indication is

magneto-to-spark plug wiring.

attained. Tighten the mounting hardware securely.

NO. 1 TERMINAL, UPPER RIGHT HAND, ON

a. Removal.

MAGNETO END CAP AS SHOWN. OTHER

(1) Use compressed air to blow dirt away from

TERMINALS FOLLOW FIRING ORDER IN

the spark plugs before removing them. This will

A CLOCKWISE ROTATION.

prevent dirt from entering the cylinders as you

remove the spark plugs.

(2) Disconnect the shielded spark plug cables

from the spark plugs (44, fig. 4-9) and remove the

spark plugs.

b. Cleaning and Inspection.

NOTE

It is normally more economical to replace the spark

plugs than for you to clean and regap them. It also

provides greater assurance that here are no hidden

cracks in the ceramic insulators which could cause

inspection instructions are given, however, in case it

is necessary for you to reuse the removed plugs.

WARNING

Clean all parts in a well-ventilated area.

Avoid inhalation of solvent fumes and

4-27. Starting Motor

prolonged exposure of the skin to

a. Removal. Remove the starting motor for

cleaning solvent. Wash exposed skin

replacement as follows:

thoroughly.

CAUTION

(1) Wipe the exterior of the spark plugs with a

Disconnect the battery cable from the

cloth dampened with cleaning solvent (fed. spec. P-

p o s i t i v e battery t e r m i n a l b e f o r e

D-680); dry thoroughly.

disconnecting any other electrical leads

(2) Check the ceramic insulators for cracks,

from the engine components. This will

porosity, and other damage.

prevent shorts which could damage the

(3) If the electrodes of the spark plugs are not

alternator, voltage regulator, and other

too badly burned, you can remove the scale and

parts.

other deposits from them. This can be done by a

(1) Disconnect the electrical lead (2, fig. 4-12)

sand-blast-type cleaner or with a contact file. Clean

to the starting motor (12) from the starter switch.

with compressed air to remove any residue.

(4) Inspect the electrodes for severe burning,

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |