|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

b. Cleaning and Inspection.

b. Cleaning and Inspection.

(1) Clean all parts with an approved cleaning

(1) Clean all parts with an approved cleaning

solvent. Take care to remove all particles from the

solvent; dry thoroughly.

screen.

(2) Inspect the blower housing for dents,

(2) Inspect the flywheel for cracks, distortion,

distortion, cracks, and punctures. Straighten minor

broken fins, and damaged keyway or bore. Check

dents and distortion. Replace if damaged beyond

the residual magnetism of the flywheel as directed

repair.

in paragraph 4-16 c (5). Replace the flywheel if it is

(3) Inspect the baffles for cracks, distortion,

damaged or has lost its magnetism.

and dents. Dents can be straightened if they will not

disrupt air flow after the repair is made. Replace

(3) Inspect the starter pulley for cracks, chips,

and distortion. Replace if damaged.

damaged parts.

c. Installation.

(4) Inspect the screen for distortion, holes,

and other damage; replace a damaged screen.

(1) Install the engine housing parts as shown

in figure 4-1, items 1 through 11. Make sure the air

(5) Replace the key if necessary. Remove all

burrs from the key, keyways, and flywheel and

has free passage around the engine when the parts

starter pulley bore before attempting to reinstall the

are installed.

parts.

(2) Install the spark plug cable on the spark

c. Installation.

plug (para 4-15 c).

(1) Position the key (18, fig. 4-1) on the

(3) Install the fuel tank, lines, and fittings,

crankshaft and install the flywheel (17) and starter

(para 4-19 c).

pulley (16). Hold the flywheel with a bar inserted

4-13. Flywheel

between the flywheel fins and install the washer

a. Removal.

(15) and nut (14). Tighten the nut to 45 foot-

(1) Remove the blower housing (para 4-12 a).

pounds.

(2) Use needle-nosed pliers to remove the

(2) Position the screen (13) in the seat of the

screen retainer (12, fig. 4-1) and screen (13) from

starter pulley and retain it with the screen retainer

the starter pulley (16).

(12).

(3) When removing the nut (14), hold the

(3) Install the blower housing (para 4-12 c).

flywheel and crankshaft from rotating, using a bar

inserted in the flywheel cooling fins, Remove the

starter pulley.

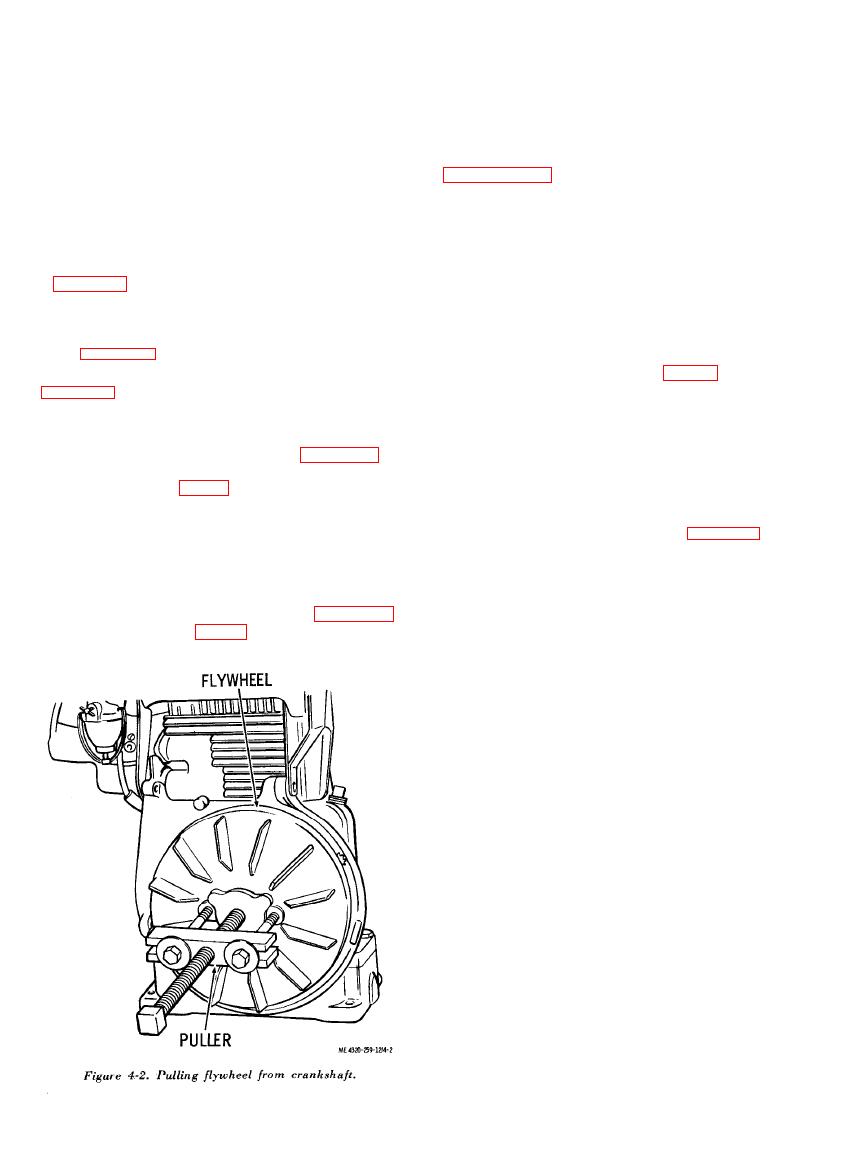

(4) Pull the flywheel (17) from the

crankshaft, using a puller as shown in figure 4-2.

Remove the key (18, fig. 4-1).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |