|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

respective shaft so that the hub face is flush with the shaft

end (fig. 6-5).

(2) Check gap and angular alignment with a

spacer bar. Gap should be exactly 1/8 inch between the

hubs as measured at 90intervals.

(3) Check offset alinement. Aline shafts so

that a straightedge will rest squarely on both hubs at the

top and also at 900 on either side.

(4) After coupling hubs are alined (para 5-15)

insert gasket through gap and hang it on either shaft.

Pack gap and grooves with lubricant before inserting grid.

(5) Insert grid. It is necessary to spread the

grid slightly to pass over the coupling teeth at the outside

diameter: to minimize this spreading, start grid at either

end and tap into place rung by rung. Do not attempt to

force grid to the bottom of the groove; it will seat readily

after all rungs are positioned. Pack spaces around grid

with as much lubricant as possible in accordance with

current lubrication order. Wipe off excess flush with top

of grid.

(6) Place seals on cover halves and slide onto

ME 4320-243-15/6-2

hubs. Installation will be easier if lube plugs are not in

place, so as to allow trapped air to escape. Position

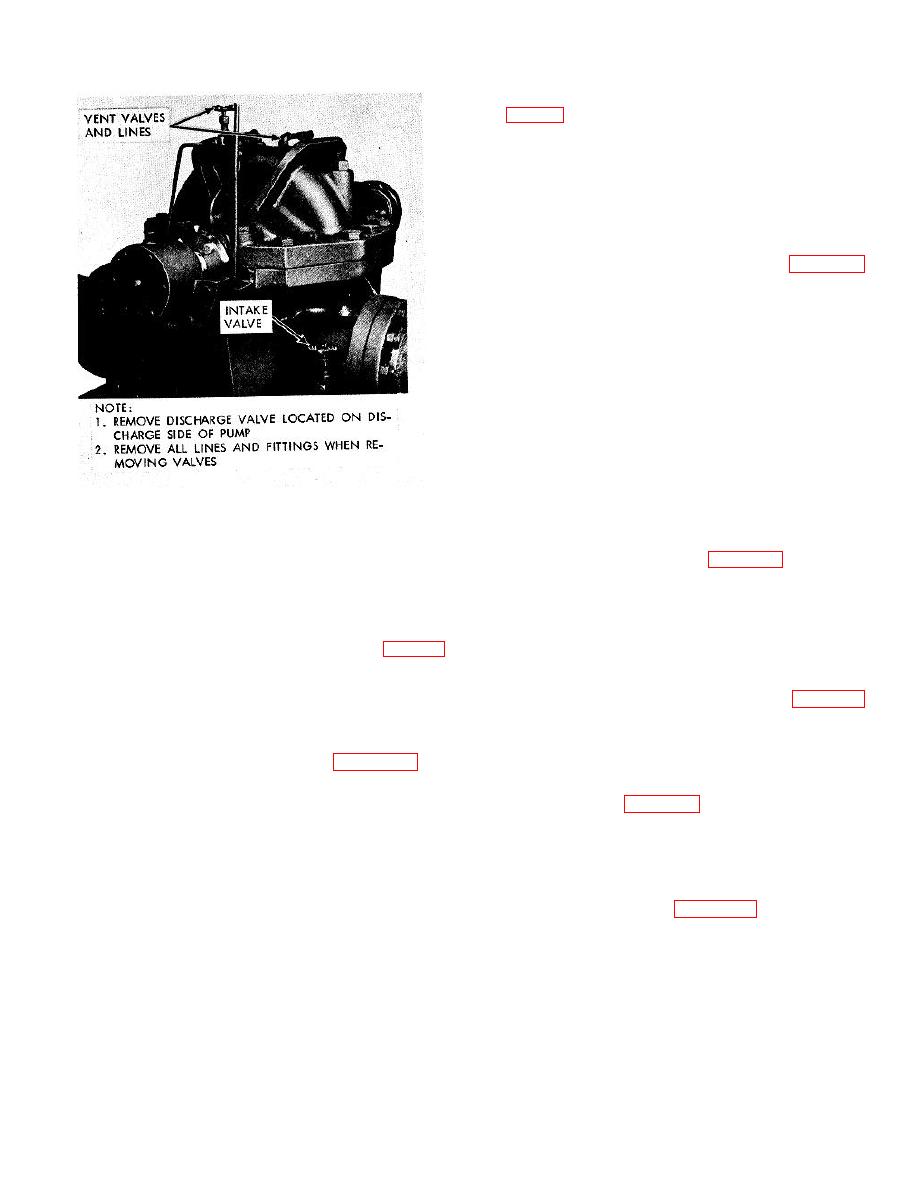

Figure 6-2. Vent, discharge and intake valves, and

covers with lube holes 180 apart and bolt gasket and

lines, removal and installation.

cover halves together, as shown in figure 6-5.

(7) With both lube plugs removed, insert fitting

d. Clean, inspect, and repair.

and fill with grease in accordance with current lubrication

6-5. Pump Coupling

order until an excess appears at the other opening, then

a. General.

The tapered-grid flexible coupling

install the lube plugs.

connecting the engine shaft and pump shaft (fig. 6-5)

utilizes a spring-steel grid coupling member to absorb

6-6. Rotating Element Assembly and Mechanical Seal

engine vibrations. The performance and life of this

coupling depend on proper installation and servicing.

above).

b. Remove and install the pump coupling as directed

b. Disassembly. Unbolt and slide the covers away

in paragraph 332.

from the coupling hubs as shown in figure 6-5. To

remove the grid, use a found rod or pry-bar that will fit

c. Remove and install the

rotating

element

conveniently into the open loop ends, and pry grid out

assembly as shown by figure 6-6.

radially in gradual stages. Proceed alternately from side

d. Disassemble the rotating element assembly in

to side, lifting each loop about halfway out of its slot until

sequence shown by key numbers in figure 67.

the end of the grid is reached. Follow the same

Reassemble in reverse sequence.

procedure once again and the grid will clear the teeth.

e. Disassemble the mechanical seal in sequence

shown by key numbers in figure 6-8. Reassemble in

c. Reassembly.

reverse sequence.

f. Clean, inspect, and repair.

(1) Place hub covers and seals on shaft before

mounting hubs.

Press or shrink each hub on its

6-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |