|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(1) Tag and remove the leads from the switch

terminals.

(2) Disconnect the line from the switch

pressure connection and connect the switch to a source of

pressure that can be varied between zero (0) and 300 psi.

(3) Connect a test lamp circuit between the

common and normally open terminals on the switch, The

lamp should not light.

(4) To adjust the switch for series operation of

the pump, slowly raise the pressure on the switch to 250 +

3 psi. The lamp should light. If the lamp does not light,

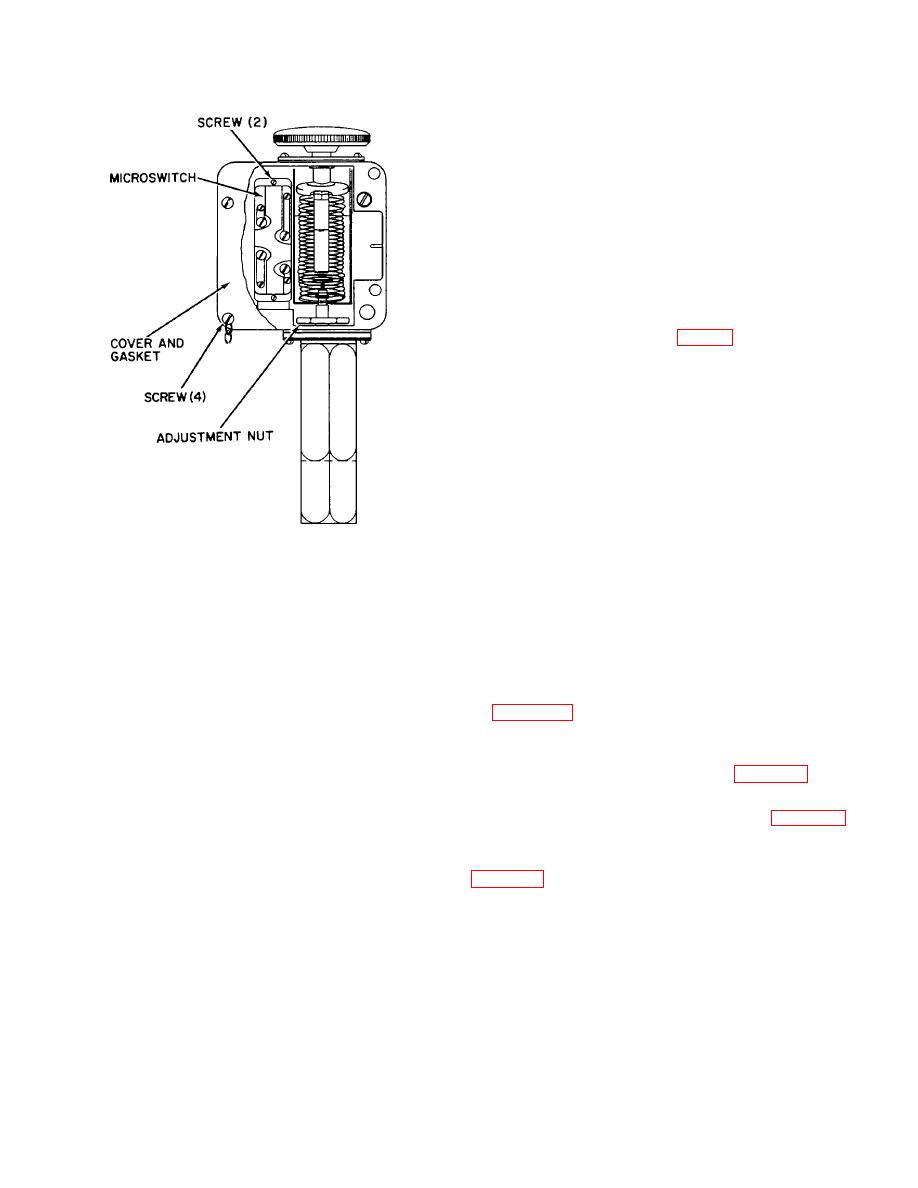

slowly turn the adjusting nut (fig. 6-1) counterclockwise to

decrease the setting, and cause the lamp to light. Turning

the adjustment nut clockwise will increase the setting.

(5) After making an adjustment, slowly

decrease the pressure until the lamp goes out, and then

repeat step (4).

(6) Repeat steps (4) and (5) until the lamp will

light at 250 + 3 psi on an increasing pressure.

(7) To adjust the switch for parallel operation of

the pump, follow steps (1) through (6) except adjust the

switch to light the lamp at 125 + 3 psi on an increasing

Figure 6-1. Pressure switch.

pressure.

clockwise to increase the setting of the switch. If the lamp

6-3. Throttle Solenoid.

does not light between 110-120 psi, turn the adjustment

nut counterclockwise to decrease the setting.

and low-pressure switches and is also connected to the

carburetor throttle valve.

Excessively high or low

(5) Slowly decrease the pressure on the switch

discharge pressure will activate the pressure switches,

until the lamp lights. The lamp should light at 100 + 3 psi,

thus tripping the throttle solenoid to idle the engine.

on a decreasing pressure. If the lamp does not light at

b. Remove and install the throttle solenoid as shown

100 + 3 psi, turn the adjustment nut clockwise to increase

by figure 3-14.

or counterclockwise to decrease the setting.

6-4. Upper Case.

(6) Repeat steps (4) and (5) until the lamp will

a. Remove and install the vent line, valves, and fluid

light at 100 + 3 psi, on a decreasing pressure.

lines from the upper case as shown by figure 6-2.

(7) To adjust the switch for parallel operation of

b. Remove and install the upper case and casing

the pump follow steps (1) through (6) except adjust the

studs in sequence shown by key numbers in figure 6-3.

switch to light the lamp at 55 + 3 psi on a decreasing

pressure.

c. During installation of the upper case, tighten

fastening bolts in sequence shown by key numbers in

d. Adjust the high pressure switch (fig.

61) as

follows:

6-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |