|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4320-237-15

(3) Inspect the discharge hoses

for

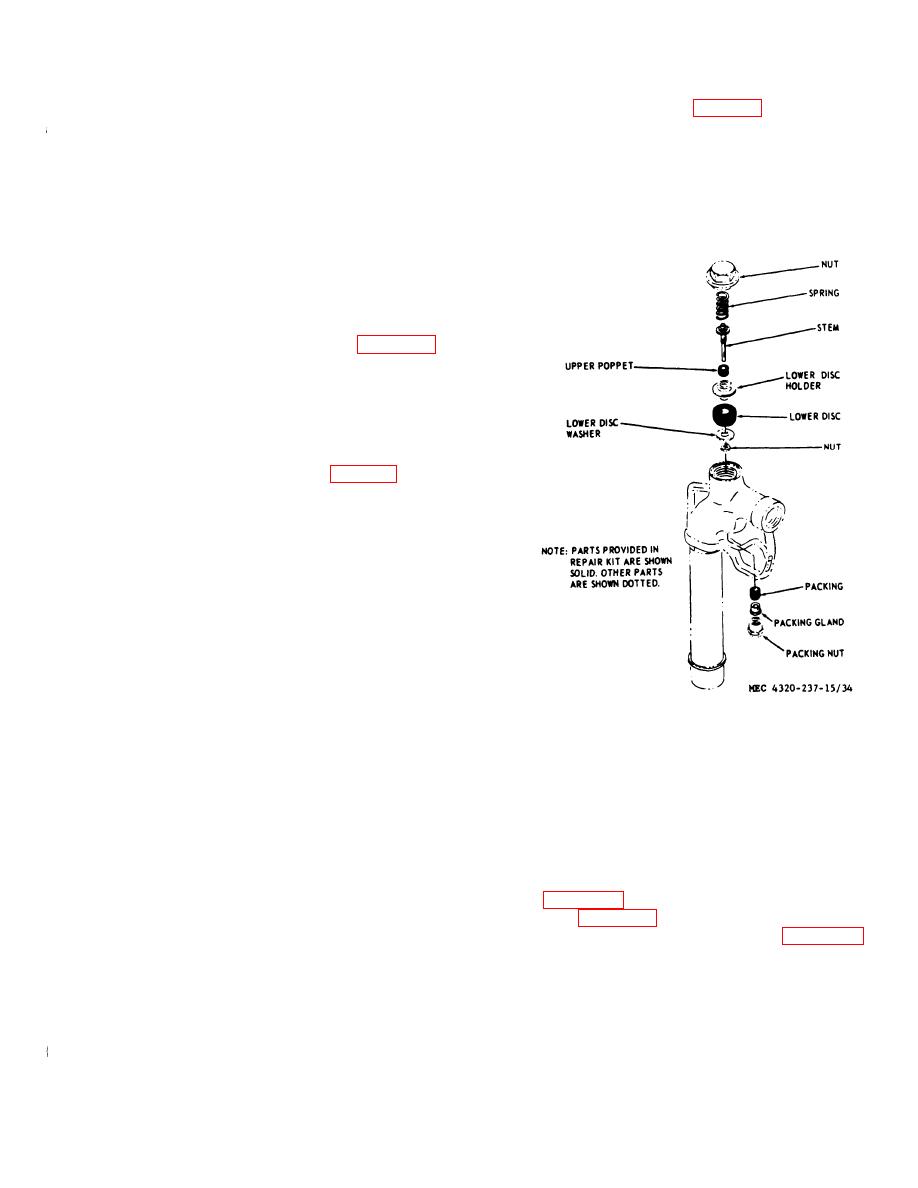

d. Reassembly. Refer to figure 34 and re-

cracks, leaks, signs of deterioration,

assemble the nozzle.

worn or damaged fittings, and other

Pull out on the coupling

e. Installation.

damage.

operating levers and position the nozzle on

(4) Inspect the discharge tee and inlet

the hose. Push in on the operating levers to

adapter for damage which could af-

join the pads

fect the sealing characteristics of the

part.

(5) Check that every female connector

has a mating plug and that every

male connector has a cap to prevent

entry of dirt. Replace all damaged

and missing parts.

c. Installation. Refer to figure 33 and in-

stall hoses and fittinings

69. Nozzles

a. Removal. Pull out on the coupling op-

crating levers to remove the nozzle from the

hose.

b. Disassembly. Refer to figure 34 and dis-

assemble the nozzle.

c. Cleaning and Inspection.

(1) Discard the removed parts for which

there are replacement in the nozzle

repair kit.

(2) Clean all remaining parts with an

approved cleaning solvent; dry thor-

oughly.

(3) Inspect the nozzle parts for cracks,

distortion. worn or damaged threads,

and other damage; replace damagd

parts. Make sure the ground cable

and pinch-type ground connector

are attached and in good condition.

Section XII. PUMP ASSEMBLY

head to prevent fluid from leaking around

70. General

the rotating shaft.

A coupling head provides the adapter to se-

71. Pump Assembly

cure the pump housing and engine together.

a. Housing and Tool Boxes Removal. Refer

One side of the coupling head bolts to the

to figure 35 and remove the pump housing,

power takeoff end of the engine. The pump

and to figure 38 and remove the tool boxes.

housing bolts to the opposite side of the cou-

b. Pump disassembly. Refer to figure 36

pling head. The pump impeller is threaded

and disassemble the pump.

and screws directly to the power takeoff end

c. Cleaning and Inspection.

of the engine crankshaft. Impeller-to-body

(1) Clean all pump parts with an ap-

clearance is regulated by shims between the

proved cleaning solvent; dry thor-

coupling head and body. A seal is installed

between the engine shaft and the coupling

oughly.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |