|

|||

|

|

|||

|

Page Title:

Section VII. ENGINE ELECTRICAL SYSTEM |

|

||

| ||||||||||

|

|

TM 5-4320-237-15

Section VII. ENGINE ELECTRICAL SYSTEM

54. General

The engine electrical system consists of the

ignition components which provide the elec-

trical spark in the cylinder to ignite the fuel-

air mixture when the piston is near top-dead-

center of the compression stroke. The sys-

tem includes the magneto, spark plug, and

spark plug lead.

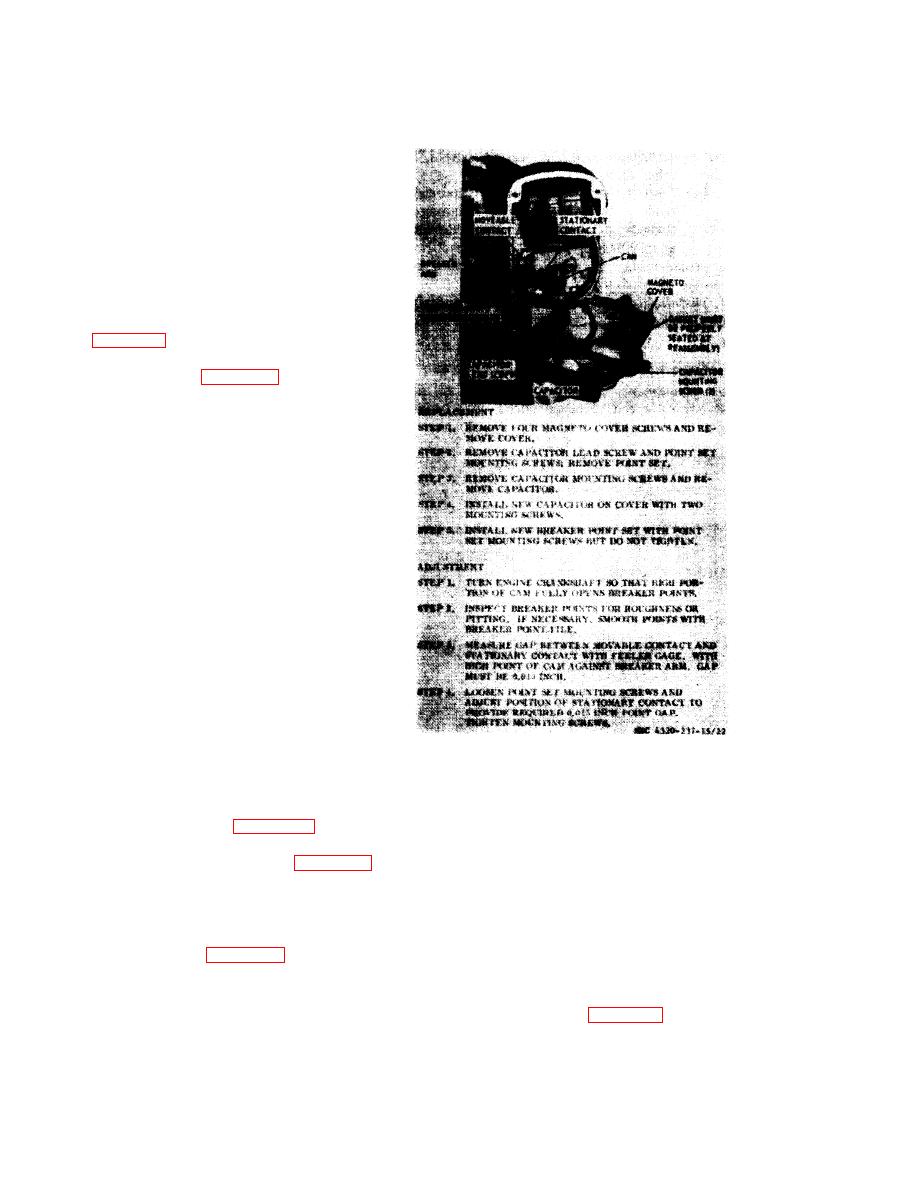

55. Magneto

a. Magneto Breaker Point Replacement.

Refer to figure 22 and replace magneto break-

er points and capacitor.

move the magneto.

c. Cleaning and Inpection.

(1) Clean all parts with a cloth dampen-

ed with an approved cleaning sol-

vent; dry thoroughly. Prevent the

entry of solvent into the inside of

the magneto.

(2) Inspect the magneto for a cracked or

damaged case, dents, worn threads,

or other visible damage. Turn the

magneto shaft by hand and check

for binding and scraping of the

shaft. Replace a damaged magneto.

(3) Replace mounting hardware that is

missing or damaged.

d. Magneto Drive Gear Replacement. Re-

move the lockwire and nut from the end of

the magneto shaft and remove the drive gear.

To install, turn the magneto shaft clockwise un-

til the impulse coupling snaps, then position

the drive gear on the shaft so that it engages

adjustment.

the key on the impulse coupling with the tim-

ing mark on the gear at the 3 o'clock position.

cleaning solvent; dry thoroughly.

(2) Inspect the spark plug cable for

cracks, frayed or damaged shielding,

and install and time magneto. Take care to

worn or damaged connection, or

follow timing instructions given in figure 23.

other damage.

The engine cannot run if the magneto is not

(3) Inspect the spark plug for cracks,

properly timed.

worn or damaged threads, corroded

or eroded terminals. If spark plug

is in good condition, gap spark plug

terminals to 0.030 inch before in-

the spark plug and cable.

stallation. If new plug is installed,

b. Cleaning and Inspection.

gap it to 0.030 inch.

(1) Clean the spark plug and cable with

c. Installation. Refer to figure 25 and in-

a cloth dampened with an approval

stall the spark plug and cable.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |