|

|||

|

|

|||

|

Page Title:

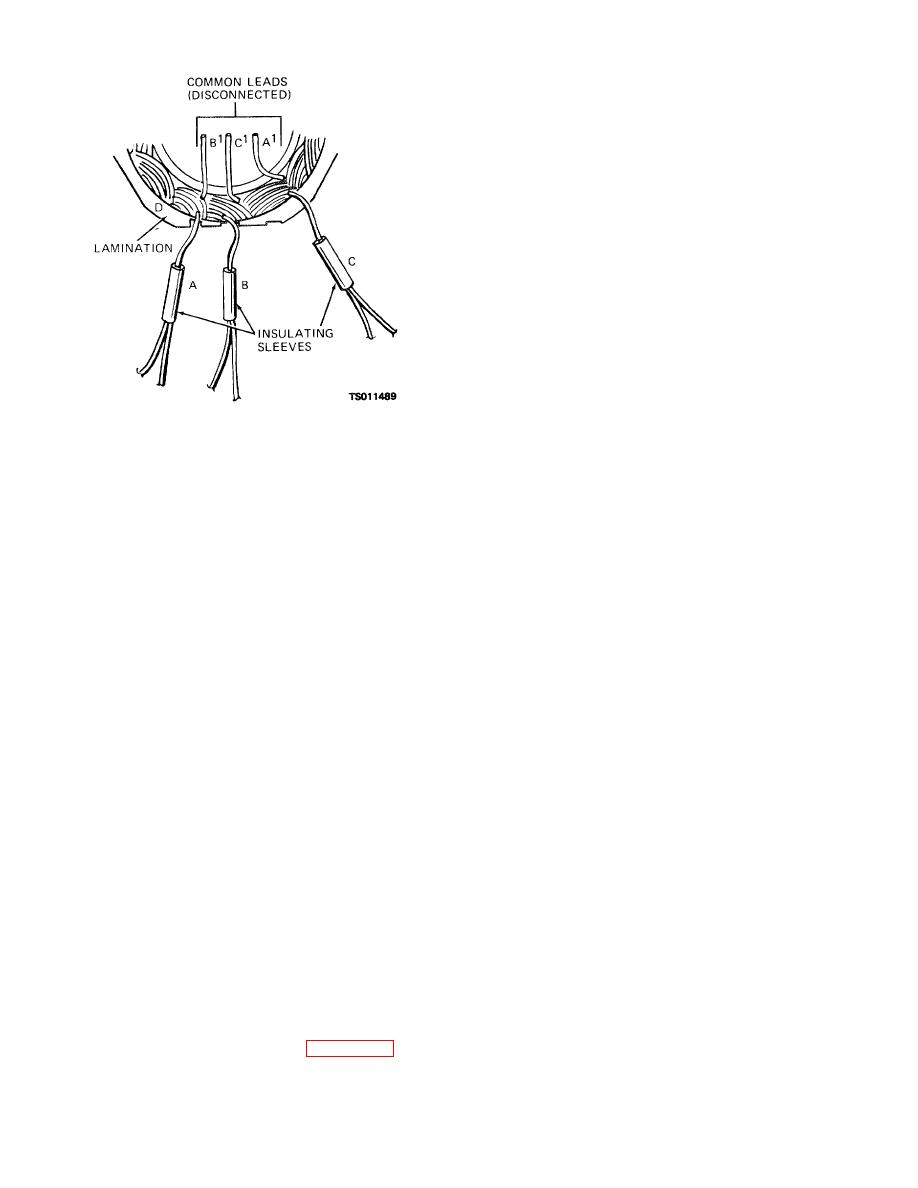

Figure 3-10. Stator test points. |

|

||

| ||||||||||

|

|

TM 5-4320-234-34

(1) Make certain that all positive and

negative rectifier diodes are soldered to the proper

stator leads and that the stator common leads have

been resoldered together after testing.

(2) Press the bearing (31) into the front

housing (32), using a driver tool that exerts pressure on

the outer bearing race only. Place the bearing retainer

(30) in recess, making certain the retainer ears line up

with openings in the housing. Use a wooden dowel to

exert pressure on the retainer when you seat its edge in

the recess.

(3) With the rotor leads in position on the

rotor assembly (46), carefully press the rear bearing (45)

onto the rotor shaft, exerting pressure on the inner race

only.

(4) Guide the rotor winding leads through

the square passage in the slip ring hub. Hand press the

slip rings (44) onto the shaft while you maintain

alinement of rotor leads and passage. Install screw (42)

and washer (43) and tighten to 45 inch-pounds. Before

Figure 3-10. Stator test points.

soldering the rotor winding leads to the slip rings, make

(3) The resistance should be infinite or test

certain that fiber insulating washers are in place on the

lamp should not light in all of the above tests. If the

inner slip ring terminals.

Wrap leads around the

resistance reading is not infinite or in the test lamp lights

terminals and solder with rosin core solder. Secure

in any test, high leakage or a short exists between stator

wires to the end of the rotor and slip rings with a

windings, or between a stator winding and the

synthetic rubber sealer. Retest the rotor circuits to

lamination. Replace the stator.

ensure that a short or ground did not develop during

(4) Test for stator continuity by connecting

repair. Refer to subparagraph e(5) above.

the ohmmeter or test lamp probes to each pair of the

(5) With the rotor properly supported on an

following test points:

arbor press, use a driver sleeve on the inner bearing

Point A to point A

race and press the front housing (32) onto the rotor.

Point B to point B

(6) Position the spacer (21), fan (19), and

Point C to point C

pulley (18) in place on the rotor shaft. Secure with the

You should have a reading of approximately 0.1 ohm or

lock washer (17) and nut (16). Tighten to 35 foot-

the test lamp should light in each test.

Infinite

pounds torque.

resistance or an unlighted test lamp indicates an open

(7) Position the insulating washers (39)

winding. Replace the stator if it fails any of the above

and sleeves (38) on the studs of the diode assemblies

tests or, if the alternator has been disassembled

(36 and 37). Position the diode assemblies in the rear

because of an electrical malfunction, replace the stator

housing so that the washers and sleeves electrically

after all other components have been checked and

insolate the diode assemblies. Secure with insulating

found to be satisfactory.

washers (35) and nuts (34).

(5) Use a multimeter to test the rotor and

(8) With rear bearing retainer (40) in place,

slip ring assembly. Connect the slip rings in series with

position the rear housing (41) over the slip ring end of

a multimeter and a 20-volt supply. There should be a

the rotor and hand press the housings together. Aline

1.20- to 2.5-amp current draw. Your multimeter should

the slots in the stator with the openings in the housings

indicate 11 to 14 ohms resistance across the slip rings.

and install the through bolts (29). Install nuts (28) and

Connect one of the multimeter or test lamp probes to

tighten to 50 to 60-inch pounds (6.9150 to 8.2980 kgm)

the rotor body and the other on either slip ring. You

torque. Turn the rotor by hand to check for binding of

should have an infinite resistance reading or the test

bearings. Rotor must rotate freely.

lamp should not light. If this does not occur, then either

(9) Install the isolation diode (26), noting

the slip rings, ring connecting leads, or rotor winding is

the proper position of the plate insulators (25, 27, and

grounded. Replace a faulty rotor.

35).

f.

Reassembly. Reassembly is essentially the

reverse of disassembly. Refer to figure 3-7. Pay

particular attention to the following:

3-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |