|

| |

TM 9-2330-272-14

4-35. BLEEDING HYDRAULIC BRAKE SYSTEM.

This Task Covers:

a.

Manual Bleeding

b.

Pressure Bleeding

Initial Setup:

Equipment Conditions:

Materials/Parts:

l Semitrailer coupled to towing vehicle (manual bleed-

c Brake fluid (item 8, Appendix E)

ing) (para 2-10).

l Rags (item 14, Appendix E)

. Master cylinder serviced (Chapter 3, Section I).

l Plastic tubing

Tools/Test Equipment:

l General mechanic’s tool kit

Personnel Required: Two

l Common no. 1 shop set

. Quart container

a.

MANUAL BLEEDING

NOTE

Perform this task at each wheel cylinder.

Ensure that fluid level in master cylinder is within )-j in. (13 mm) from top at all times

during task to avoid allowing air to enter hydraulic brake system.

A drain pan should be used to catch any draining brake fluid. Ensure that all spills are

cleaned up.

Plastic tubing should be approximately 18 in. (46 cm) long.

1.

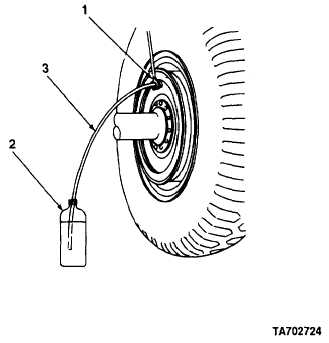

Clean wheel cylinder bleeder valve (1). Connect

plastic tubing (3) to bleeder valve.

NOTE

Ensure that end of plastic tubing remains sub-

merged in brake fluid for entire procedure.

2.

Fill container (2) approximately halfway with brake

fluid and place free end of plastic tubing (3) in

container.

3.

Have an assistant depress and hold brake pedal.

Open wheel cylinder bleeder valve (1), allowing

brake fluid to flow into container (2).

4.

When brake fluid contains no air bubbles, close

wheel cylinder bleeder valve (1) and disconnect

plastic tubing (3).

4-60

|