|

| |

TM 55-2915-335-30&P

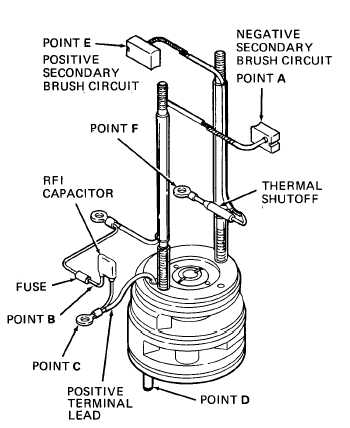

2-23. ELECTRICAL CIRCUITS - lNSPECT/REPLACE

2-23

This task covers: Replacement of negative and positive secondary brush circuits.

INITIAL SETUP

Tools:

Aircraft Electrician’s Tool Kit, NSN 5180-00-323-4915

Soldering Iron NSN 3439-00-853-8760, or equivalent

Heater Gun, 200 to 500 deg F,

NSN 4940-00-785-1162, or equivalent

Brush Holder Centering Tool, Item 1, Appendix D

Personnel Required:

68F Aircraft Electrician

66-Series Inspector

Equipment Condition:

Pump-end brush holder assembly removed from

housing PARA 2-20.

Material/Parts:

Solder, Rosin-Core, QQS-571E

Electrical Wire, 18 AWG,

NSN

-

-

-

Heat Shrink Tubing 0.250 Inch I.D.

NSN 5970-00-935- 0082

Heat Shrink Tubing, 0.062 Inch I.D.,

NSN 5970-00- 935-0083

Thread Locking Compound, NSN 8030-00-111-2762

1. INSPECTION

a.

b.

c.

d.

e.

f.

Check for continuity between points A and B. If

open, replace negative secondary brush circuit.

Check for continuity between points B and C. If

zero ohms, RFI capacitor is shorted. If shorted,

replace negative secondary brush circuit.

Check for continuity between points C and D. If

open, replace positive terminal lead per the in-

structions and illustrations in paragraph 2-24.

Check for continuity between point D and impel-

ler housing. If zero ohms, positive terminal is

shorted to the housing. If shorted, replace positive

terminal per instructions and illustrations in

paragraph 2-24.

Check for continuity between points E and F. If

open, replace positive secondary brush circuit.

Check general condition of all wiring. If insulation

or shrink tubing is cracked or charred, replace

circuit. Check brush solder joints for loose fit or

cracking. Resolder loose or cracked brush solder

joints.

GO TO NEXT PAGE

2-80

|