|

| |

TM 55-2915-335-30&P

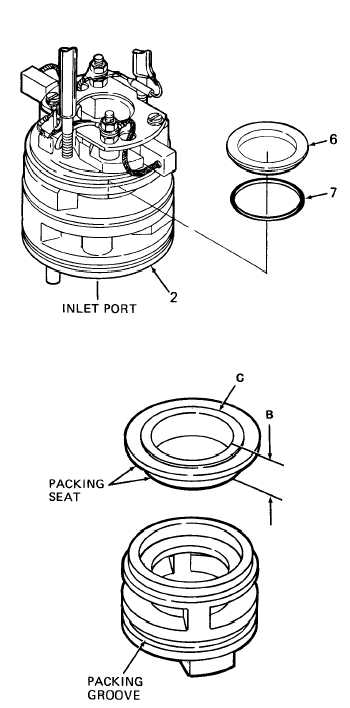

2-21. PUMP COVER AND INLET SEAL - lNSPECT/REPAIR/REPLACE (Cont)

2-21

c.

d.

Reach index finger into inlet port of housing (2)

and push inlet seal (6) up. Remove inlet seal from

impeller chamber. Remove and discard preformed

packing (7).

Cleaning solvent can be hazardous to

your health. Use solvent only in well venti-

lated areas. Avoid breathing solvent

vapors. Do not use solvent near an open

flame or other source of high heat. Al-

ways wear gloves, apron, and goggles

when using cleaning solvent. Store solvent

in approved metal container only.

Wash impeller housing (2), pump cover (4), and

inlet seal (6) with non-woven cleaning cloth (Item

1, Appendix C) and dry cleaning solvent (Item 7,

Appendix C).

2. INSPECTION

a.

b.

c.

d.

Run your finger along the packing groove edges of

the pump cover. Feel for any scratches or sharp

edges that may damage preformed packing.

Remove sharp edges of nicks or scratches using

500 or 600 grit, wet or dry emery paper. After

sanding, clean surface with solvent.

If edges of packing groove is chipped or broken,

replace pump cover.

Visually check drain port threads. If damaged, re-

place pump cover.

Run your finger along the packing seat of inlet

seal (6). Feel for any scratches or sharp edges that

may damage preformed packing. Remove sharp

edges of nicks or scratches using 500 or 600 grit,

wet or dry emery paper.

GO TO NEXT PAGE

2-73

|