|

| |

TM 55-2915-335-30&P

2-17. COVER-END BRUSH HOLDER ASSEMBLY - lNSPECT/REPAIR (Cont)

2-17

3. ASSEMBLY

a.

b.

c.

d.

e.

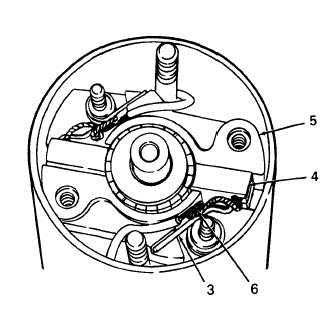

Install brush holder (5) in cartridge.

Position brush (4) in brush holder. Slide brush

against commutator. Hold brush in place with in-

dex finger.

Place brush spring (3) over stud. Insert hooked

tang into spring slot at back of brush. Use needle-

nose pliers to grasp straight tang of spring. Twist

straight tang counterclockwise around stud. Place

spring tang behind keeper ridge of brush holder,

as shown. Push tang down to assure that spring is

fully seated.

Bare brush leads must not be allowed to

contact field tube when motor is in use.

Leaving brush leads exposed may damage

the pump motor.

Hold installed brush (4) and spring tang (3) in

place. Place brush lead in wire trench. Place solder

joint (6) and shunt lead into gap between spring

and brush. Shunt lead must not hang out beyond

edge of brush holder (5). Shunt lead must be free

to move with brush in holder.

Repeat Steps a through d to install opposite brush

set. Be careful not to move the brush holder too

much. Hold down on installed brush and spring

tang while installing second brush set.

GO TO NEXT PAGE

2-52

|