|

| |

TM 55-2915-335-30&P

2-14. INLET SHUTOFF VALVE - lNSPECT/REPLACE (Cont)

2-14

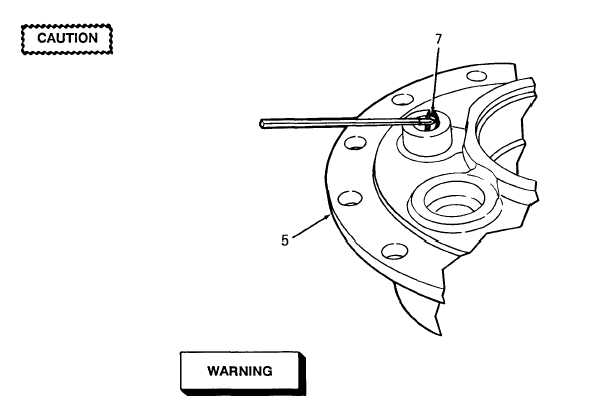

Do not use metal probe to remove

preformed packing from valve stem bore.

Scratching or scoring valve stem bore may

cause pump to leak fuel.

d. Remove preformed packing (7) from valve stem

bore in pump housing (5). Use sharpened lead

pencil, toothpick, or plastic probe to remove pack-

ing from seat. Do not use any metal probe that

might score packing seat.

2. CLEANING

Compressed air aimed at the skin can cause serious injury or death.

Wear goggles and never use over 30 psi (207 kPa) of compressed air

for cleaning.

Cleaning solvent can be hazardous to your health. Use solvent only

in well ventilated areas. Avoid breathing solvent vapors. Do not use

solvent near an open flame or other source of high heat. Always wear

gloves, apron, and goggles when using cleaning solvent. Store solvent

in approved metal container only.

a. Wash pump housing and valve parts in dry cleaning solvent (Item 7, Appendix C).

b. Blow-dry valve stem bore with compressed air, 30 psi (207 kpa) maximum.

GO TO NEXT PAGE

2-37

|