|

| |

TM 55-2915-335-30&P

2-13. BYPASS VALVE - REPLACE

2-13

This task covers: Removal and replacement of bypass valve.

INITIAL SETUP

Tools

Material/Parts:

Aircraft Electrician’s Tool Kit,NSN 5180-00-323-4915

Cleaning Cloth, Nonwoven, NSN 8305-00-753-2967

Drill, Hand Electric, 1/4 Inch Size,

Dry Cleaning Solvent, NSN 6850-00-274-5421

NSN 5130-00-889-8994, or equivalent

500 or 600 grit, wet or dry emery paper

Twist Drill, No. 4, NSN 5133-00-189-9249

Tape

Die And Tap Set, NSN 5136-00-357-7504

Disk, Solid, NSN 2040-01-170-6502

Cartridge Pulling Tool, Item 4, Appendix D

Nylon Ball, NSN 2040-01-170-6502

Pulling Tool Adapter, Item 3, Appendix D

Cold Chisel, 1/4 Inch Cut, NSN 5110-00-234-1927

Equipment Condition:

Press Arbor, Hand Operated, 1/2 Ton Pressure,

Canister removed from pump housing PARA 2-11

NSN 3444-00-243-2654, or equivalent

Center Punch, NSN 5120-00-223-1015

Personnel Required:

68F Aircraft Electrician

68D Powertrain Repairer

1. REMOVAL

a.

b.

c.

d.

e.

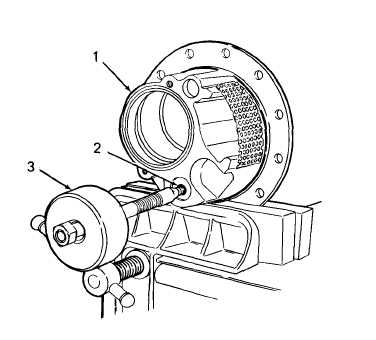

Plug all open ports in pump housing (l). Clean

rags can be used as packing material. Cover small

openings with tape.

Always use plastic jaws or padding to hold

pump housing in vise. Failure to use soft

jaws may damage the housing.

Secure flange of pump housing in soft-jawed vise.

Support housing by mounting near the bypass

valve port, as shown.

Using a center punch, lightly punch drill starting

point at about center of solid disk (2).

Use a number 4 drill bit and drill through center

of solid disk (2). Gently drill until drill bit just

breaks through disk. Tap hole with 1/4-28 tap.

Install pull tool adapter (Figure 3, Appendix D)

on cartridge pulling tool (Figure 4, Appendix D).

Thread pulling tool (3) into port plug solid disk

(2). Slide hammer of pulling tool against bolt head

to remove disk. Remove and discard port plug

disk. Remove nylon ball from pump housing.

GO TO NEXT PAGE

2-33

|