|

| |

TM 55-2915-335-30&P

2-11. PUMP CANISTER - INSPECT/REPLACE

2-11

This task covers: Inspection and replacement of the pump housing canister.

INITIAL SETUP

Tools:

Material/Parts:

Aircraft Electrician’s Tool Kit, NSN 5180-00-323-4915

Thread Locking Compound, NSN 8030-00-111-2762

Wire Brush, NSN 7920-00-291-5815

Cleaning Cloth, Nonwoven, NSN 8305-00-753-2967

Dry Cleaning Solvent, NSN 6850-00-274-5421

Personnel Required:

500 or 600 grit, wet or dry, emery paper

68F Aircraft Electrician

White Petrolatum, NSN 6505-00-133-8025

Preformed Packing, NSN 5330-00-476-7406

Ecquipment Condition:

Umbrella Check Valve, NSN 4510-01-070-5681

Pump cartridge removed from housing PARA 2-10

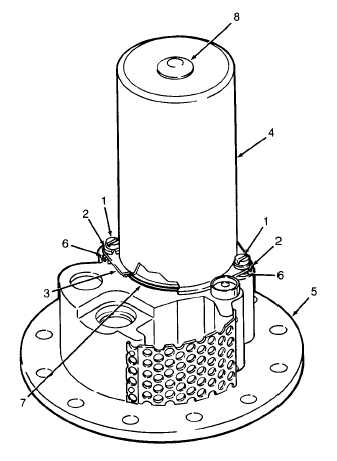

1. REMOVAL

a.

b.

c.

d.

Remove machine screws (1) and lockwashers (2).

Lift canister flange (3) and pump canister (4) from

pump housing (5).

Remove spacer washers (6). Remove preformed

packing (7) from packing groove in pump housing.

Discard preformed packing.

Remove umbrella check valve (8) from pump

canister (4) and discard check valve.

2. CLEANING

a.

Cleaning solvent can be hazardous to

your health. Use solvent only in well venti-

lated areas. Avoid breathing solvent

vapors. Do not use solvent near an open

flame or other source of high heat. Al-

ways wear gloves, apron, and goggles

when using cleaning solvent. Store solvent

in approved metal container only.

Rinse pump canister (4), canister flange (3), and

spacer washers (6) in dry cleaning solvent (Item 7,

Appendix C). Wipe off and dry parts with non-

woven cleaning cloth (Item 1, Appendix C).

GO TO NEXT PAGE

2-25

|