|

| |

TM 55-2915-335-30&P

Table 2-2. Maintenance Troubleshooting - Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

4. MOTOR RUNS, LOW FLOW AND/OR PRESSURE (Cont)

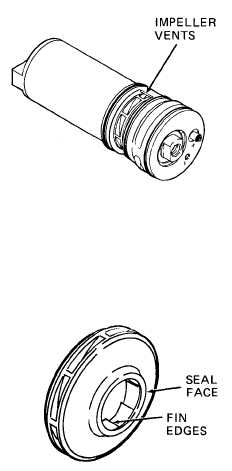

Step 4. Check for clogged impeller. Remove

pump cartridge from housing (paragraph

2-10). Rotate impeller. Look for a buildup of

slime in impeller vents. If no slime buildup is

seen, proceed to Step 5.

If there is slime in the impeller

vents, disassemble and clean

pump components per

paragraphs 2-11 through 2-24.

Step 5. Check impeller and seal face. Remove

field tube, armature, and impeller (paragraphs

2-18 and 2-19). Look for grooved or dull seal

face or worn impeller fins. If impeller and seal

face is good, proceed to Step 6.

Inspect fin edges for damage. If

defective, replace impeller per

instructions and illustrations in

paragraph 2-18. If impeller seal

face looks grooved or dull,

repair per instructions and il-

lustrations in paragraph 2-19.

Step 6. Inlet seal or pump cover packings are

damaged.

Replace preformed packings on

inlet seal and pump cover pack-

ings per instructions and il-

lustrations in paragraph 2-21.

5. PUMP STALLS UNDER LOAD

Step 1. Check for brushes not seating well on commutator. Remove pump cartridge from housing per

paragraph 2-10. Check for shunt lead caught on spring. Inspect brush contact surface for wear and chips or

cracks (secondary brushes paragraph 2-17; primary brushes paragraph 2-20). Check for brush springs out of

place. If brushes, springs and shunt leads are good, proceed to Step 2.

If brush is not seating well on commutator, adjust shunt lead or spring positions, as needed.

Inspect and replace worn, chipped, or cracked brushes per instructions and illustrations in

paragraphs 2-17 and 2-20.

2-14

|