|

| |

TM 55-2915-335-30&P

Table 2-2. Maintenance Troubleshooting - Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

4.

MOTOR RUNS, LOW FLOW AND/OR PRESSURE.

Running motor over one minute without a

flow of liquid may cause permanent

damage to the motor.

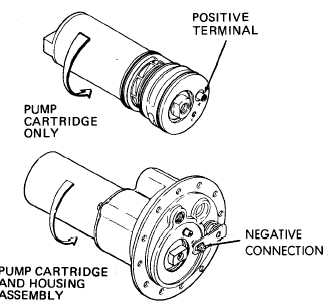

Step 1. Check for motor running backwards.

Connect pump to 28 vdc power supply. Start

pump and check that startup torque of motor

is counterclockwise, as shown. If startup torque

is clockwise, field tube is reversed on cartridge.

If motor rotation is correct, go to Step 2 if

checking assembled pump cartridge and hous-

ing assembly. If checking pump cartridge only

go to Step 4.

Remove field tube and install

correctly per instructions and il-

lustrations in paragraph 2-18.

Step 2. Determine if low flow and/or pressure is

due to malfunction in cartridge or housing as-

sembly. Remove cartridge from housing per

paragraph 2-10. Install cartridge in test tank

per paragraph 2-25 and repeat flow test, Table

2-1, block 8 and pressure test Table 2-1, block

11.

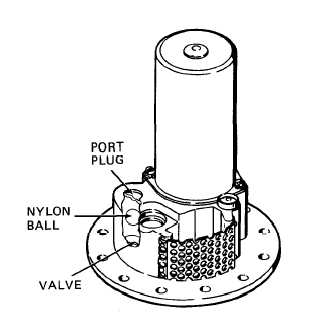

Step 3.

valve.

If cartridge passes test, bypass

valve in housing is defective. In-

spect housing valve seat and

ball per Step 3.

If cartridge fails test, isolate

problem in cartridge; go to

Step 4.

Check for faulty or jammed bypass

Inspect ball and valve seat per

the instructions and illustra-

tions in paragraph 2-13.

2-13

|