|

| |

TM 55-2915-335-30&P

Table 2-1. Fault Isolation - Continued

From block 6

l

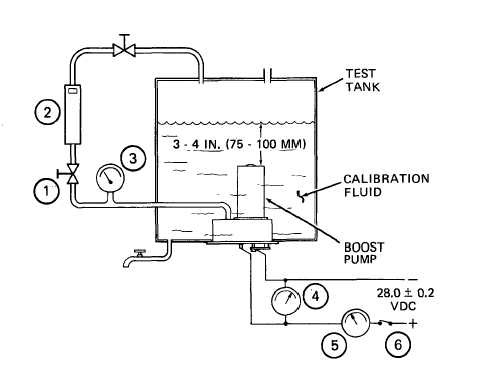

Check pump for maximum flow rate.

NOTE

After installing pump in test tank, DO NOT per-

form test procedures detailed in paragraph 2-

25. Test pump as follows:

l

Install pump or cartridge in test tank per

final test procedure (paragraph 2-25). Set

up for pressure and flow check as in-

structed.

l

Turn power ON.

l

Adjust voltage to 28 VDC.

l

Open flow control valve (1).

l

Observe fuel flow at flowmeter (2).

Does pump reach 1000 PPH (454 kg/hr) flow

rate?

LEGEND

1. FLOW CONTROL VALVE

2. FLOWMETER

3. PRESSURE GAGE

4. VOLTMETER

5. AMMETER

6. POWER ON/OFF SWITCH

After completing fault isolation, and before

proceeding to the malfunction test or in-

spection, the following is required: Close

flow control valve, adjust voltage to 0 VDC,

turn power OFF and if necessary remove

complete pump assembly or pump cartridge

from test tank per paragraph 2-25, step 6.

If pressure reads 0 PPH (0 kg/hr), proceed to

Malfunction Number 3 of Table 2-2.

If pressure reads more than 0 PPH (0 kg/hr),

proceed to Malfunction Number 4 of Table 2-2.

To block 11

2-4

|