|

| |

TM 5-4320-313-14

6-1. CYLINDER HEAD AND VALVE ASSEMBLY - Continued.

c. Inspection - Continued.

(4) Check that inside diameter of each valve guide does not exceed 0.2779 inch (7.059 mm).

(5) Check that valve seat angle does not exceed 45 degrees.

d. Repair. (Refer to figure 6-2).

(1) If the inside diameter of a cylinder head valve guide exceeds 0.2779 inch (7.059 mm), replace valve guide.

Press out valve guide.

(2) From cylinder head bottom, push valve guide out of cylinder head. Insert new valve guide into cylinder

head. Install new valve guide by pressing in. Minimum inserting pressure is 220 inch-pounds (245 cm-kg).

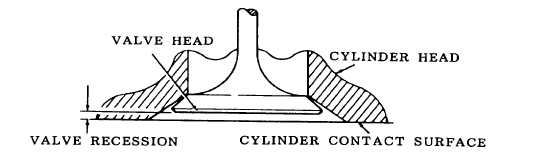

Figure 6-2. Checking Valve Recession.

(3) Ream the inside diameter of the valve guide to 0.2755/0.2760 inch (7.000/7.009 mm) using hand reamer.

(4) Repair defective cylinder head valve seats by grinding with a 45 degree valve seat cutter.

(5) The cylinder contact surface of the cylinder head can be repaired by machining. Remove up to a maximum

of 0.0196 inch (0.5 mm) of metal provided the minimum valve recession is maintained.

(6) Replace any valves that show head warping, burning, or other damage.

(7) Replace valves that have seriously scratched or scuffed stems, or pitted, ridged, or cracked faces, or heads.

(8) Replace valves that have a valve head diameter of less than 1.197 inch (30.4 mm).

6-4

|