|

| |

TM 5-4320-308-13

5-3. REPAIR/REPLACE CONNECTING ROD (Continued)

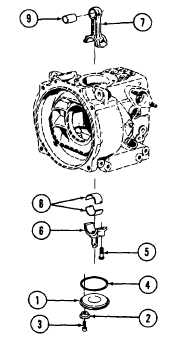

7 Disassemble connecting rod and carefully insert bearing halves (8). The bottom half has a hole which fits into

connecting rod cup. Reassemble connecting rod with two Allen screws. Tighten screws following procedures

described in preceding step 5.

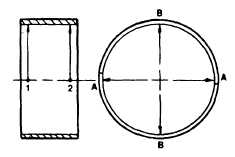

8 Measure inside diameter of bearing. Measure at points 1 and 2

along axes A and B. Measurements should be 1. 6541 to 1. 6525

inches (42.016 to 41. 974 mm).

9 If any measurement is outside the tolerance limits, replace the

bearing. Make sure that measurements at points 1 and 2 are not

different nor outside the tolerance limits, indicating that bearing is

wearing in a conical shape.

10 Make sure measurements along axes A and B are not different nor

outside the tolerance limits, indicating the bearing is wearing in an oval shape.

11 If bearing is out-of-round, replace it. Follow procedure described in paragraph 5-7. Also check cylinder and

piston for unusual wear. Follow procedures described in paragraphs 4-18 and 4-19.

REPAIR:

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard's Solvent) is

potentially dangerous. Avoid repeated and prolonged breathing

of vapors and skin contact with the liquid. Do not use near open

flame, arcing equipment, or other ignition sources. Always wear

eye protection and protective clothing. The flash point of P-D-

680 is 100° to 138°F (38° to 59°C).

Death or serious injury could occur if compressed air is directed

against the skin. Do not use compressed air for cleaning or

drying unless the pressure is/has been reduced to 30 psi (2. 06

bar) or less. When working with compressed air, always use chip

guards, eye protection, and other personal protective equipment.

1 Clean rod bushing (9) and connecting rod (7) bore with dry cleaning solvent

and dry with compressed air.

5-8

|