|

| |

TM 5-4320-308-13

5-3. REPAIR/REPLACE CONNECTING ROD (Continued)

INSPECTION:

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard's Solvent) is potentially dangerous. Avoid

repeated and prolonged breathing of vapors and skin contact with the liquid. Do not use near

open flame, arcing equipment, or other ignition sources. Always wear eye protection and

protective clothing. The flash point of P-D-680 is 100° to 138°F (38° to 59°C).

Death or serious injury could occur if compressed air is directed against the skin. Do not use

compressed air for cleaning or drying unless the pressure is/has been reduced to 30 psi (2.06 bar)

or less. When working with compressed air, always use chip guards, eye protection, and other

personal protective equipment.

1 Clean connecting rod components with dry cleaning solvent. Remove any carbon deposits with a wire brush.

Clean inside surface of rod bushing (9), both connecting rod halves (6 and 7), and bearing (8). Blow

compressed air through the drilled oil passage in connecting rod to clean connecting rod and rod bushing.

2 Visually inspect connecting rod for bending, warping, cracking, rust, or other damage. Check for cracks using

MIL-1-6868 magnetic particle inspection. Replace if twisted or bent. Grind or replace if indications of cracks

are revealed by magnetic particle inspection.

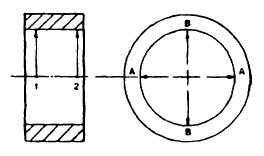

3 Measure and record rod bushing (9) inside diameter. Measure at points 1 and 2 along axes A and B.

Measurements should be 0. 9951 to 0. 9858 inch (25. 276 to 25. 040 mm). If any measurement is outside

these limits, replace rod bushing.

4 Inspect upper and lower bearing halves (8) for excessive wear, scoring, pitting, flaking, etching, and signs of

overheating. Inspect bearing backs for bright spots (bearing moving in supports).

5 Temporarily assemble connecting rod with two new Allen screws and without bearings. Using a torque wrench,

tighten screws to 29. 50 foot pounds (40 N. m). Apply some oil to threads and contact surfaces.

6 Measure inside diameter of connecting rod bearing bore. Measurement should be 1. 8114 to 1. 8107 inches

(46. 010 to 45. 994 mm). If measurement is outside specified limits, replace connecting rod.

5-7

|