|

| |

TM 5-4320-308-13

4-19.

INSPECT/REPAIR/REPLACE PISTON (Continued)

ASSEMBLY:

1 If cylinder has been replaced, piston must also be replaced.

CAUTION

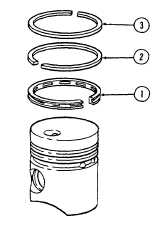

Piston rings are marked TOP and should be installed as marked. Piston ring

breakage may occur if rings are opened more than necessary when removing or

installing them. Do not strain rings.

2

If piston replacement is necessary, piston rings must also be replaced.

3

Install piston rings with piston ring pliers 612 090 00. Install oil control ring (1), cast iron compression ring (2),

and chrome compression ring (3) in order. Be careful not to strain rings by opening them too wide during

installation. Make sure that the piston ring gaps are equally spaced around the piston 120 degrees from each

other.

4 Install new circlip (1) in lip groove of piston (3) gudgeon bore.

CAUTION

When installing piston, make sure piston or connecting rod do not knock against

crankcase. This could result in serious damage to piston or connecting rod.

5

Insert connecting rod (4) into bottom of piston (3). Make sure that opening of combustion chamber is on the

flywheel side.

6

Insert gudgeon pin (2) into piston (3) gudgeon bore and through rod bushing of connecting rod (4). Push in

gudgeon pin until it contacts installed circlip (1) and stops.

7

Install new circlip (5).

4-57

|