|

| |

TM 5-4320-308-13

4-19.

INSPECT/REPAIR/REPLACE PISTON (Continued)

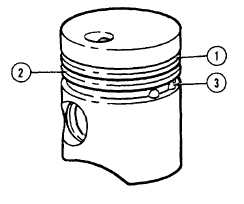

5

Measure piston compression ring groove (1) width. Measurement should be 0.0826 to 0.0843 inch (2.100 to

2.143 mm). If measurement is greater than 0.0843 inch (2.143 mm), replace piston.

6

Measure piston ring groove (2) width. Measurement should be 0.0811 to 0.0908 inch (2.060 to 2.310 mm). If

measurement is greater than 0.0908 inch (2. 310 mm), replace piston.

7

Measure piston oil control ring groove (3) width. Measurement should be 0.1582 to 0.1599 inch (4.020 to 4.060

mm). If measurement is greater than 0.1599 inch (4.060 mm), replace piston.

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard's Solvent) is potentially

dangerous. Avoid repeated and prolonged breathing of vapors and skin contact

with the liquid. Do not use near open flame, arcing equipment, or other ignition

sources. Always wear eye protection and protective clothing. The flash point of

P-D-680 is 100° to 138° F (38° to 59°C).

Death or serious injury could occur if compressed air is directed against the skin.

Do not use compressed air for cleaning or drying unless the pressure is/has been

reduced to 30 psi (2.06 bar) or less. When working with compressed air, always

use chip guards, eye protection, and other personal protective equipment.

8

If any ring groove width measurements are smaller than the minimum values given above, piston ring grooves

may be clogged with carbon deposits. Clean piston with dry cleaning solvent. Dry with compressed air. Take

measurements again.

9

Inspect gudgeon pin for scoring, fretting, pitting, or indications of overheating. If severely damaged, replace

gudgeon pin.

REPAIR:

Remove slight scoring or fretting on piston with crocus cloth. Clean and repeat procedure if necessary.

4-56

|