|

| |

TM 5-4320-306-24

4-12.

REPLACE/REPAIR CRANKSHAFT ASSEMBLY (Continued)

3

Passing 3/4 inch (19.05 mm) rope or fabric lifting slings through cylinder bores 1 and 6, secure the crankshaft so

it will not fall from the crankcase when the bearing caps are removed.

4

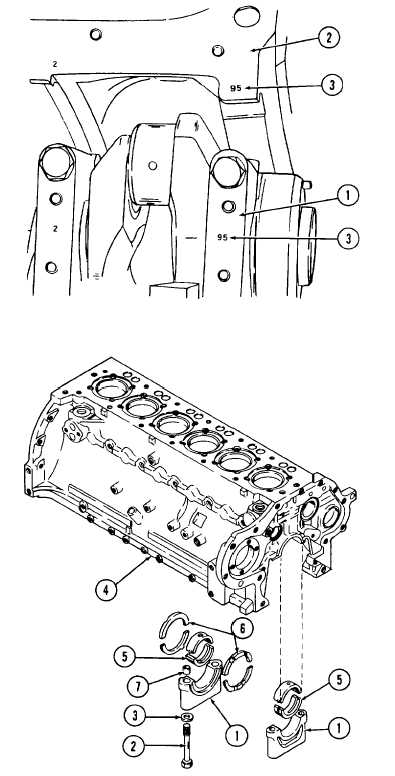

Check that each bearing cap (1) is

marked with a corresponding matchmark

on the crankcase (2). The matchmarks

must indicate direction of match as well

as location.

5

If there are no existing matchmarks,

mark each bearing cap (1) and its

corresponding

position

with

an

identification number (3). The number

and direction of the number should be

the same for each cap and crankcase

position.

6

Starting with the front and rear bearing

caps (1), and working toward the center

bearing caps, remove the bolts (2) and

washers (3) that secure each bearing cap

to the crankcase (4).

7

Remove bearing caps (1), main bearings

(5), and stop rings (6). Be sure to note

location of the two stop rings to aid in

installation. Remove dowel bushings (7)

that aline each bearing cap to crankcase.

8

Follow

procedure

described

in

paragraph 4-13 for inspection, repair, or

replacement of bearing cap, bracket, and

main bearing.

9

Release the slings holding the crankshaft

in position and remove it from the

crankcase.

4-94

|