|

| |

TM 5-4320-306-24

4-11

REPLACE/REPAIR CONNECTING ROD ASSEMBLY (Continued)

13

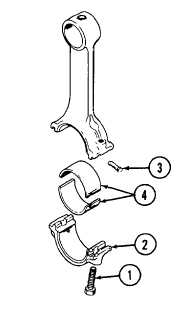

Remove big-end bolts (1), bearing cap (2), and dowel pin (3), and carefully insert bearing shells (4) Reinsert pin

and tighten big-end bolts following procedure described in step 9 above.

14

Check bearing shell bore

a

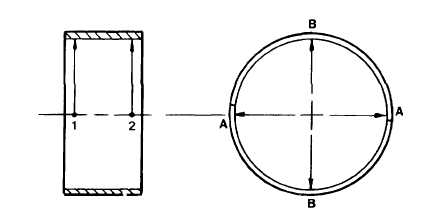

Measure with inside micrometer at points 1 and 2 and along axes A and B. Measurement should be 2

5209 to 2.5224 inches (64.031 to 64.069 mm).

b.

If any measurement is outside the tolerance limits, replace the bearing shells.

c

Make sure that measurements at points 1 and 2 are not different nor outside the tolerance limits indicating

that bearing shell is wearing in a conical shape.

d

Make sure measurements along axes A and B are not different nor outside the tolerance limits indicating

bearing shell is wearing in an oval shape.

e

If bearing shell is wearing out-of-round, replace it and check the crankpin on the crankshaft. Follow

procedure described in paragraph 4-12 Also check pistons and cylinders for unusual wear. Follow

procedures described in paragraphs 4-9 and 4-10.

4-87

|