|

| |

TM 5-4320-306-24

4-10. REPLACE/REPAIR PISTON ASSEMBLY (Continued)

15

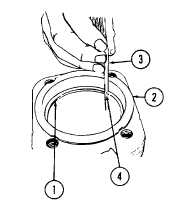

Measure piston ring gap.

a.

Use piston to push piston rings (1), one at a time, down into cylinder (2). With feeler gage (3), measure

ring gap (4) according to the following chart.

NOTE

Push ring in far enough to be in the normal area of ring travel, about 1.18 to 1.57 inches (30 to 40 mm).

NORMAL RING

RING GAP

GAP

WEAR LIMIT

inches

inches

PISTON RING

(millimeters)

(millimeters)

Compression

0.0138 to 0.0217

0.1575

rings

(0.35 to 0.55)

(4.00)

Oil control

0.0008 to 0.0157

0.0984

ring

(0.25 to 0.40)

(2.50)

b.

If compression ring gap (4) measurements are less than 0.0138 inch (0.35 mm), the gap may be widened

by very carefully filing or stoning. See REPAIR step 2 for details.

c.

If the double-chamfered oil control ring gap measurement is less than 0.0098 inch (0.25 mm), replace the

double-chamfered ring.

d.

If any ring gap measurement is greater than 0.1575 inch (4.0 mm), replace the piston ring set.

16

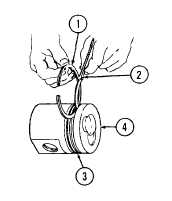

Measure piston ring side clearance.

a.

Measure piston ring (1) side clearance with new piston rings only. Measure side clearance of each piston

ring with feeler gage (2) in its corresponding piston ring groove (3) in accordance with the following chart.

4-78

|