|

| |

TM 5-4320-306-24

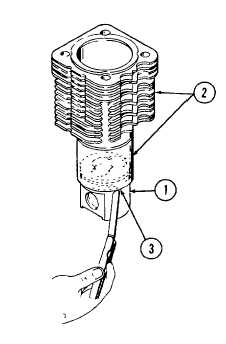

4-10. REPLACE/REPAIR PISTON ASSEMBLY (Continued)

pin with micrometer (3) at several points along the length of the pin. The diameter should be 1.3777 to 1.3780

inches (34.994 to 35.0 mm). The diameter should not be greater than 1.3780 inches (35.0 mm) under normal

conditions. However, if it is, replace piston pin and recheck piston bore measurements. Replace piston if

necessary. If piston pin is worn and any diameter measurements are less than 1.3777 inches (34.994 mm),

replace piston pin.

CAUTION

Piston and cylinder damage may result if pistons are not returned to their original cylinders. Observe

matchmarks so that mixups do not occur.

14

Insert each piston (1) in its respective cylinder (2) or replacement, and measure the piston skirt-to-cylinder

clearance with feeler gage (3). If clearance is not within 0.0032 to 0.0166 inch (0.081 to 0.421 mm), inspect

pistons and replace if necessary.

NOTE

Each piston is fitted with three rings: two compression rings and a double-chamfered oil control ring. The

top compression or trapezoidal ring can be identified by the bright chrome plating. The second

compression or taper ring can be identified by its cast iron construction. A double-chamfered oil control

ring is used in the oil ring groove. All new piston rings must be installed whenever a piston is removed or

replaced, or when a new cylinder is installed.

4-77

|