|

| |

TM 5-4320-306-24

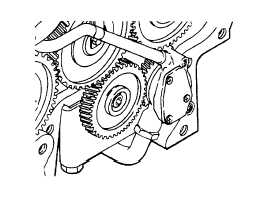

3-11. REPLACE/REPAIR OIL PUMP ASSEMBLY (Continued)

9 Oil pump gear-to-crankshaft gear backlash

should be 0.039 to 0 078 inch (1 to 2 mm).

Adjust backlash by sliding oil pump in toward

crankcase to decrease backlash. Increase back-

lash by sliding oil pump away from crankcase.

Tighten screws to 25 ft-lb (35 N•m)

10 Using bolts (1 ) and lockwashers (2), secure assembled pipe clips (3) and suction pipe (5) to

the lower bearing cap.

11 Move suction pipe (5) in pipe clips (3) as required to install a new duplex ring (6) and the

suction pipe end into the intake (lower, threaded) port of oil pump (7).

12 Tighten cap screw/nut (4) to secure the suction pipe (5) and duplex ring (6) in oil pump (7).

13 Make sure reference markings on idler, crankshaft, camshaft, and injection pump gears are

alined properly. Secure idler gear by tightening the screw (12) to 22.13 ft-lb (30 N•m) torque.

Then tighten screw an additional 60 degrees.

14 Tighten bolts (1) and screws (8) to a torque of 25.81 ft-lb (35 N•m)

3-58

|