|

| |

TM 5-4320-305-24

2-18. REPLACE/REPAIR SUCTION ASSEMBLY, STRAINER ASSEMBLY,

AND GATE VALVE (Continued)

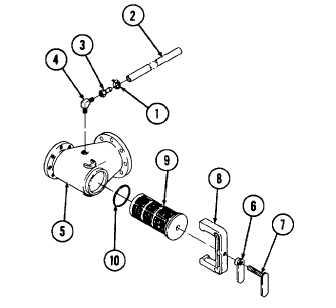

7 Loosen hose clamp (1) and remove suction pressure

hose (2) from reducer (3).

8 Remove elbow (4) and reducer (3) from strainer body

(5).

9 Unlock locking lever (6) and remove lever bolt (7).

10 Remove strainer clamp (8) from strainer body (5).

11 Remove strainer (9) and preformed packing (10).

Discard preformed packing.

CLEANING/INSPECTION/REPAIR:

1 Inspect flanges, gate valve, strainer body, and strainer clamp for cracks, rust, corrosion, and for dam- aged or

stripped threads. Inspect mounting surfaces. Make sure they are smooth and flat with no nicks or burrs.

2 Repair minor nicks or burrs and/or smooth out mounting surfaces with crocus abrasive cloth. Clean interior or

mounting surfaces. Clean and refinish outside surfaces. Remove only a minimal amount of surface material; replace

parts if necessary.

3 Inspect suction pressure hose (2). Replace if brittle, cracked, or deteriorated. Inspect hose clamp (1), reducer (3), and

90-degree elbow (4) for damage, rust, or corrosion. Replace parts if severely damaged or rusted.

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard's Solvent) is

potentially dangerous. Avoid repeated and prolonged breathing of

vapors and skin contact with the liquid. Do not use near open

flame, arcing equipment, or other ignition source. Always wear eye

protection and protective clothing. The flash point of P-D-680 is

100° to 138°F (38° to 59°C).

Death or serious injury could occur if compressed air is directed

against the skin. Do not use compressed air for cleaning or drying

unless the pressure is/has been reduced to 30 psi (2.11 kgcm2) or

less. When working with compressed air always use chip guards,

eye protection, and other personal protective equipment.

4 Clean strainer with dry cleaning solvent. Dry with compressed air.

5 Inspect strainer for damage. Replace if severely damaged.

2-73

|