|

| |

TM 5-4320-305-24

2-13. TEST/REPLACE/REPAIR BATTERY CABLE ASSEMBLIES, BATTERIES, AND CHARGING RECEPTACLE

(Continued)

3.

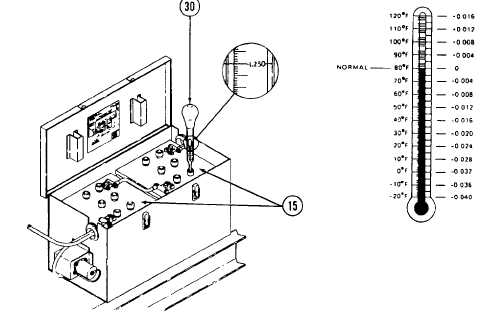

Remove filler cap (29). Using a hydrometer (30) check the specific gravity of the electrolyte. The specific gravity

of a fully charged battery must be 1.250 minimum at 80°F (26°C). Measure the temperature of the battery

electrolyte with an accurate thermometer. Compare the electrolyte temperature and the hydrometer specific

gravity reading to the battery condition chart. Add or subtract (from your specific gravity reading) the decimal next

to the temperature in degrees F that closely approximates the obtained electrolyte temperature. If the temperature

corrected reading is below 1.250, charge the battery.

WARNING

Leave filler caps installed while battery is being charged. Charge battery in a well-ventilated

area. Do not smoke or use open flame or spark-producing equipment in the vicinity of charging

battery.

NOTE

The 6TN and 6TL batteries can not be mixed or matched. However, maintenance-free batteries

cannot be mixed or matched with military batteries. Use an electrolyte with a specific gravity of

1.280. Do not use tropical electrolyte, which will lower the battery reserve capacity.

4

If battery will not hold the charge, discard and replace with new battery. Add electrolyte to new battery and charge

before installation.

5

Inspect terminal lugs (3, 7, and 11), screws (28), and nuts (2,6, and 10) for corrosion. If corroded, clean with a

solution of baking soda and water. Inspect screws and nuts for damaged threads. Replace if damaged.

6

Inspect ends of cables (4, 8, and 12) for corrosion. If corroded, clean with a solution of baking soda and water.

2-38

Change 2

|