|

| |

TM 5-4320-305-10

2-5.

INITIAL ADJUSTMENTS AND DAILY CHECKS (Continued)

d.

Perform all category B preventive maintenance checks and services (PMCS) listed in Table 2-2. Report

any problems to organizational maintenance.

e.

If pumping assembly has not been operated for one week, perform all category B and W PMCS listed in

Table 2-2. Report any problems to organizational maintenance.

f.

If pumping assembly has not been operated for more than a month, perform all PMCS listed in Table 2-2.

Report any problems to organizational maintenance.

2-6.

OPERATING PROCEDURE

a.

Setup instructions. Proper selection of an operating site is important for efficient and trouble- free pump

operation. Since the centrifugal pump unit is self-contained, it can be moved to the most favorable operating site. Select

an operating site with the following characteristics.

(1)

Locate the centrifugal pump unit on a hard, flat surface capable of sustaining its weight. If the unit is

located in sandy or marshy terrain, place planks, logs, or any type of available dunnage parallel to the

axle under each wheel for stability. Keep both the length of the suction hose and the height of the

suction lift to a minimum.

(2)

Locate unit as close as possible to the liquid to be pumped with the suction (inlet) side toward the

source. In hoseline operations, the units staged down-line from the first unit should be positioned with

the suction and discharge ports alined with the hoseline.

(3)

Allow adequate space to permit support of the suction and discharge hoses where they enter the pump.

b.

Securing trailer at site.

(1)

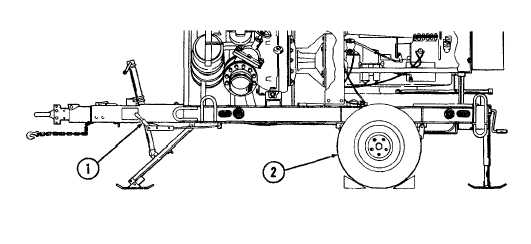

Park the trailer in position for pumping. The automatic inertia braking system does not function when

the trailer assembly is parked. Pull hand brake lever (1) toward the front end of trailer to lock parking

brakes. Block wheels (2) in both directions.

2-66

|