|

| |

TM 5-4320-305-10

2-15.

EMERGENCY PROCEDURES (Continued)

After centrifugal pump unit is primed and pumping, maintain engine idle speed until engine

warm-up cycle is complete.

(10) Run the centrifugal pump unit with engine at idle speed for a few minutes. Adjust MANUAL

THROTTLE CONTROL knob until desired operating speed is reached. Refer to paragraph c.

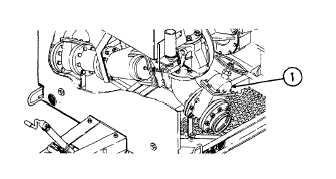

(11) Partially close the discharge gate

valve (1) to fill the hose slowly and

guard

against

excessive

shock

pressure to fittings. As the discharge

hose fills, open the discharge gate

valve until it is adjusted to the

required discharge flow rate.

Impeller cavitation occurs when engine speed is increased beyond the point of maximum suction

vacuum. Cavitation is harmful to the pump unit and should be avoided at all times. Cavitation

can be detected by a very loud cracking noise in the pump housing.

NOTE

Engine speed and pump discharge will vary in accordance with the output demand and the

physical layout of the system. When there is no increase in vacuum (suction) as indicated on the

suction gage, maximum pumping capacity has been reached.

d.

Adjustments. Engine speed and pump discharge pressure are controlled with the MANUAL THROTTLE

CONTROL knob (1). Press button in center of MANUAL THROTTLE CONTROL knob and pull out to increase engine

speed and pump discharge pressure; push in to decrease engine speed and pump discharge pressure. Adjust the

MANUAL THROTTLE CONTROL until the required speed and discharge pressure are reached. Engine speed and pump

discharge pressure vary with the weight of the liquid being pumped and the demands of the pumping application. See

the pump performance data plate, located on the noise shield, to determine the correct flow rate for the liquid being

pumped. Pump capacities are shown in US gallons per minute (cubic meters per hour). Discharge pressures are shown

in 2-86psi and feet of head for 1.000, 0.72, and 0.85 specific gravity liquids. Engine speed is shown in 100 rpm

increments from 2000 to 2400 rpm (maximum governed speed). Pump and engine assembly will give satisfactory life

and performance when operated in accordance with the pump performance data.

2-86

|