|

| |

TM 5-4320-305-10

2-15.

EMERGENCY PROCEDURES (Continued)

c.

Starting. Instructions for starting, running, and stopping the engine are located on the front panel of the

retrofit kit.

(1)

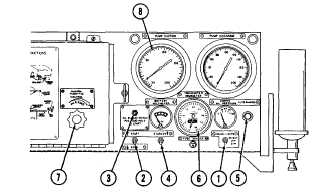

Set PANEL LIGHTS switch (1) to the BRIGHT or DIM position to turn on panel lights.

(2)

Set START/STOP switch (2) to START position.

(3)

Press OIL BYPASS switch (3) located above START/STOP switch and hold in while engaging starter.

This switch bypasses the low oil pressure circuit. When oil pressure is below normal, the low oil

pressure circuit stops the engine. Oil pressure is normally low when starting the engine. This switch

bypasses the circuit until the oil pressure reaches approximately 40 psi (276 kPa).

If engine fails to start within 10 seconds, release STARTER switch; do not attempt starting again

until starter motor stops turning. Failure to comply with this rule may result in serious damage to

the starter motor.

(4)

Hold STARTER switch (4) in UP

position until engine starts. If the

engine fails to start after four periods

of

cranking,

see

troubleshooting

procedures in Chapter 3.

(5)

Continue

pressing

OIL

BYPASS

switch and observe oil pressure gage.

After oil pressure builds up over 40

psi (276 kPa), release the OIL

BYPASS switch.

(6)

Check that ALTERNATOR light (5)

has gone out. This means batteries

are being adequately charged by

alternator.

(7)

After starting the engine, observe TACHOMETER (6). Use MANUAL THROTTLE CONTROL knob (7)

to adjust engine speed (approximately 800 to 900 rpm's).

(8)

Observe PUMP SUCTION GAGE (8); the gage should show a vacuum. The pump may not prime

immediately because the suction hose must first fill with liquid. If the pump fails to prime within 5

minutes, stop the engine and check for leaks. If there are no leaks, and the pump fails to prime, refer

to Table 3-1, Troubleshooting.

(9)

The check valve on the discharge manifold assembly is forced open when discharge pressure is high

enough to initiate flow.

2-85

|