|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4320-273-14

Table 4-2. Troubleshooting -- Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

ENGINE -- Continued

Remove spark plug from number 1 cylinder. Place finger over bole and crank engine over until compressed

air can be felt against finger as piston rises.

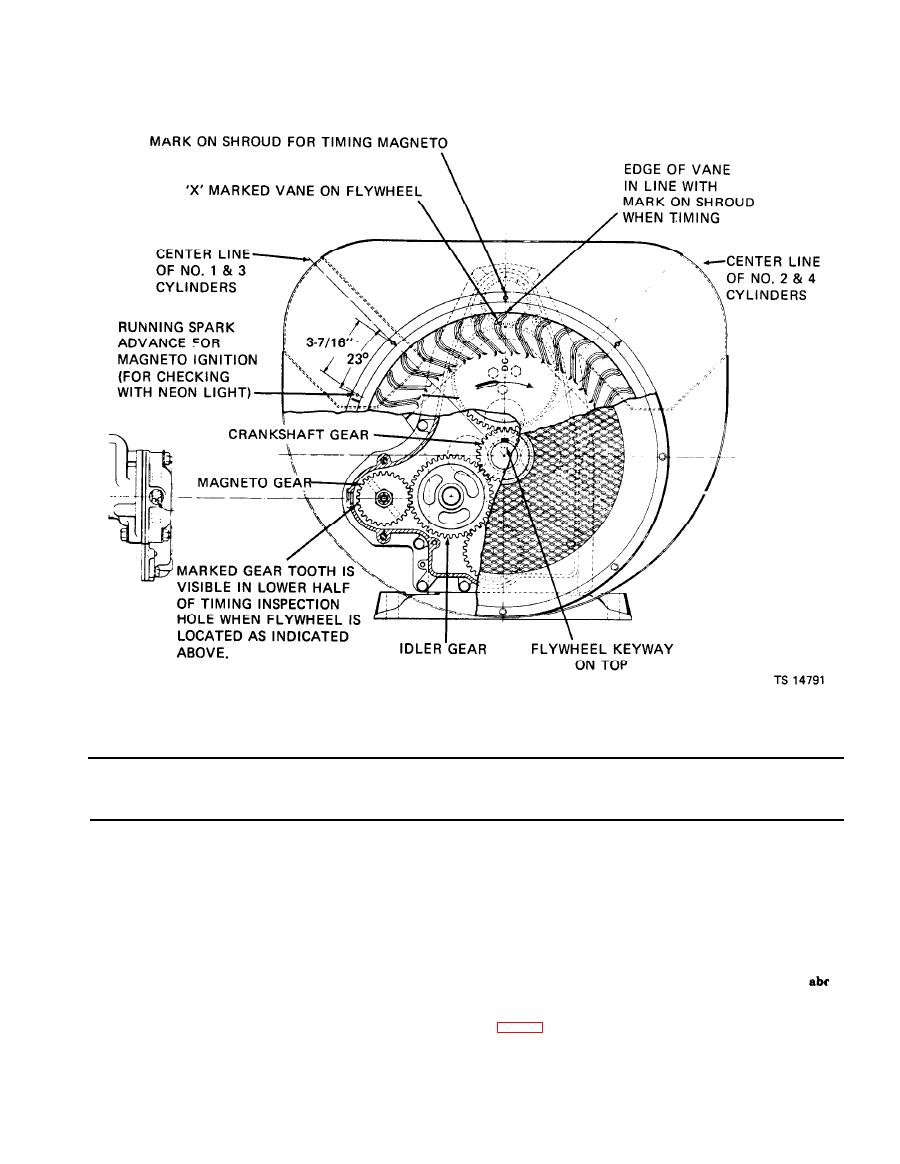

Continue cranking until the DC mark on the flywheel is aligned with the timing mark on the shroud. The

engine should be held at this dead center setting.

Disconnect the oil line and remove pipe elbow from gear cover at magneto mounting flange. This will

provide an inspection hole.

Determine the number 1 cylinder firing position of the magneto by inserting an ignition cable into the num-

ber 1 terminal on the end cap.

Mount magneto in vise thoroughly lined with protective cloth. Hold spark plug terminal at other end

1/8 inch (0.32 cm) from magneto body and turn magneto gear in clockwise rotation until terminal spa'

Hold gear in this position.

Remove magneto from vise and mount magneto (5, fig. 4-3) and gasket (14) to engine. Mesh gears so magneto

is in place. The gear tooth marked with an "X" will be visible through lower half of inspection hole.

Secure magneto by installing screw (13) and lockwasher (12). Install lockwashers (11) and nuts (9 and 10).

Connect spark plug cables and ground switch lead.

Adjust breaker point assembly on new magneto as follows:

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |