|

|||

|

|

|||

|

Page Title:

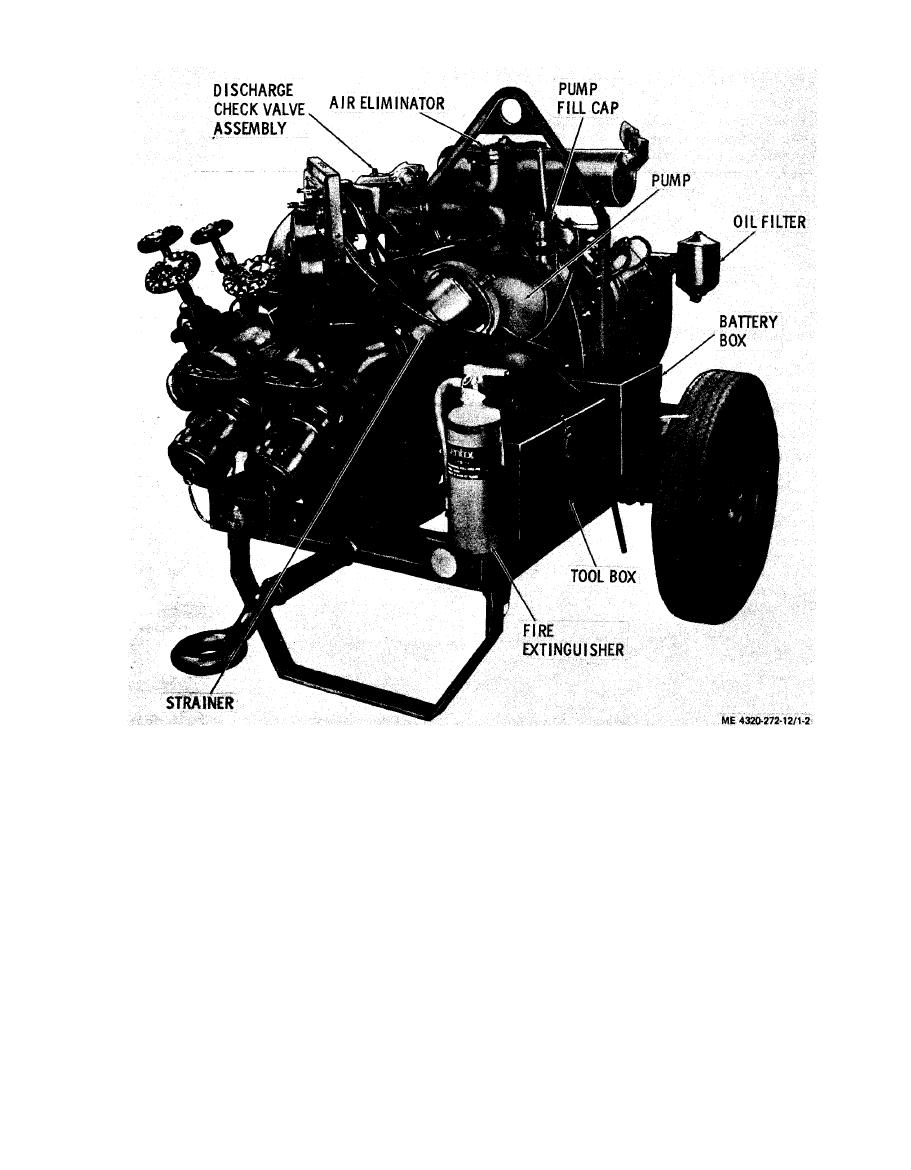

Figure 1-2. Pumping assembly, left three-quarter front view. |

|

||

| ||||||||||

|

|

b. A 4 i n c h s u c t i o n p i p e a s s e m b l y c o n s i s t i n g

c. T h e e n g i n e i s a V - t y p e , f o u r - c y l i n d e r , a i r -

primarily of a strainer, manifold, and two gate

c o o l e d , pressure-lubricated, four-stroke-cycle unit

valves, is secured to the front of the pump body. A 4

with an L-head. Engine speed is controlled by the

i n c h discharge pipe assembly, consisting primarily

i n t e r - o p e r a t i o n of a governor and carburetor. The

o f air eliminator, check valve, manifold, and two

engine is cooled by a flow of air, circulated over the

gate valves, is secured to the top of the pump body.

heads by a combination fan-flywheel enclosed in a

T h e coupling joins the engine crankcase with the

s h e e t metal shroud. The engine uses an electrical

p u m p body, providing correct spacing and proper

s t a r t i n g motor, has magneto ignition, and uses a

a l i n e m e n t of the parts. The impeller is threaded

f l y w h e e l alternator to maintain the charge of the

onto the engine crankshaft and held secure by the

battery.

d. The engine and pump are secured to a two-

o p p o s i n g rotation of the engine. The impeller is

enclosed in a close-fitting volute to provide efficient

wheeled welded frame. The frame weldment

p u m p i n g operation. Replaceable wear plates at the

c o n s i s t s primarily of a drawbar, fixed axle, hub

front and rear of the impeller take most of the

assemblies, and pneumatic tires.

internal pump wear.

e. T h e m a i n t e n a n c e p a r a g r a p h s o f t h i s m a n u a l

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |