|

|||

|

|

|||

|

Page Title:

Section II. MOVEMENT TO A NEW WORKSITE |

|

||

| ||||||||||

|

|

the building. Make sure that the diameter of the exhaust

(3) Support the discharge line at or near the

piping is large enough to prevent excessive back

pump to prevent strain.

pressure in the engine.

Warning: Do not operate the pump unit in an

enclosed area unless exhaust gases are piped to the

e. If an auxiliary fuel supply is to be used, connect

outside. Inhalation of exhaust fumes will result in

a fuel line between the source of supply and the 3-way

serious illness or death.

fuel source selector valve (1, fig. 2-4) on the fuel tank.

Operate the fuel valve to the AUX position.

d. If the centrifugal pump is operated indoors,

provide piping to carry exhaust gases to the outside of

Section II. MOVEMENT TO A NEW WORKSITE

2-3. Dismantling for Movement

charge line before disconnecting it from the pump.

Dismantle the pump for movement to a new worksite as

Drain the lines into a suitable container.

follows:

b. Remove the drain plug (fig. 1-1) from the

bottom of the pump to drain the pump housing. Catch

a. Disconnect the suction line and discharge line

the fluid in a suitable container.

from the pump. If possible, drain the dis-

c. If there is any chance of debris entering the

pump suction and discharge openings, cover the

openingwith tape.

d. If installed, disconnect the fuel line from the 3-

way fuel source selector valve (1, fig. 2-4) on the fuel

tank.

e. Disconnect any exhaust piping from the pump.

f. Drain the engine as necessary. On the left side

of the engine at the bottom of the housing are the oil

cooler drain plug (1, fig. 2-1), radiator coolant drain plug

(2), block coolant drain plug (3) and oil pan drain plug

(4). On the side of the engine is the carburetor bowl

drain plug (4, fig. 2-3).

g. When moving the pump assembly, do not

attempt to slide pump on its skid base for any long

distance. A lifting bail (fig. 1-2) is provided to facilitate

hoisting the pump onto a suitable carrier.

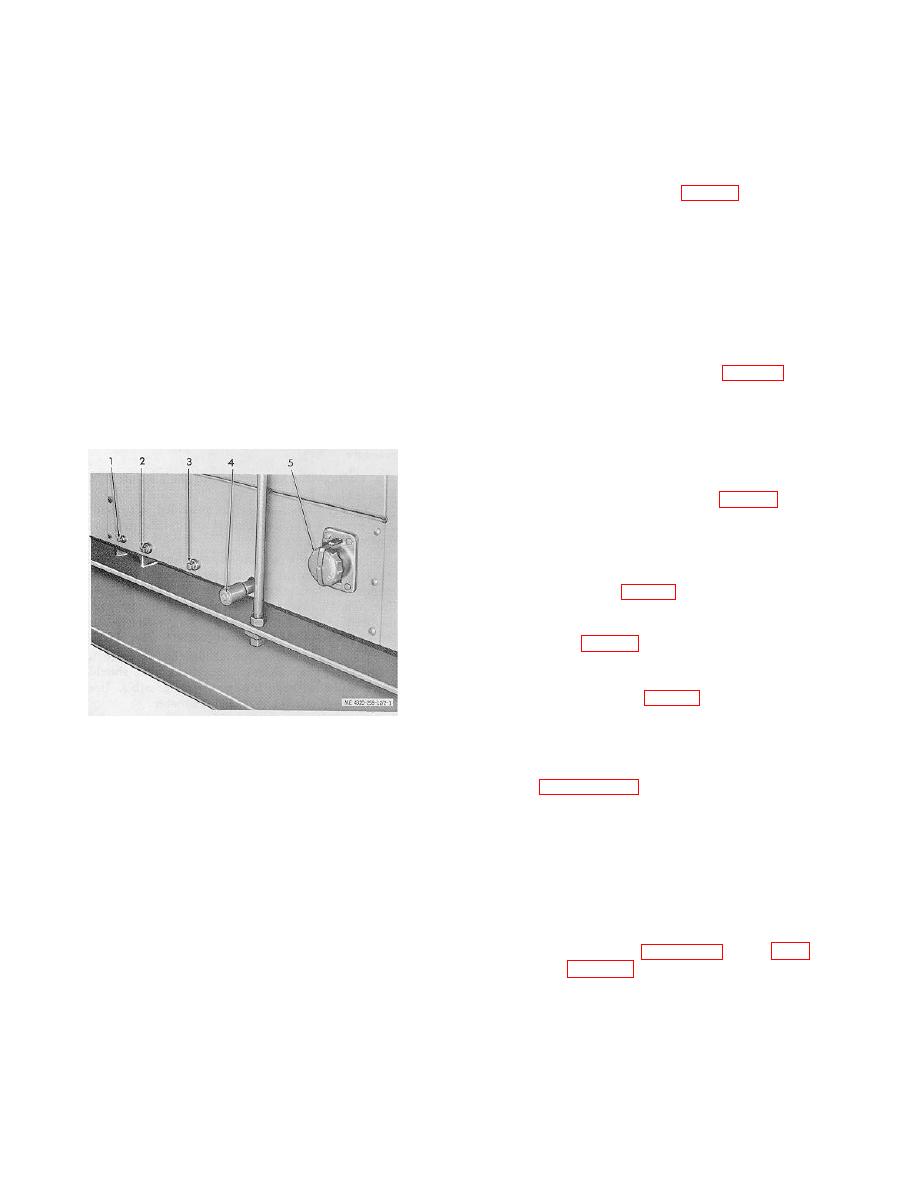

1. Oil cooler drain plug

4. Oil pan drain plug

2. Radiator coolant drain 5. Battery charging

2-4. Reinstallation after Movement

plug receptacle

3. Block coolant drain

Refer to paragraph 2-2 for installation instructions.

plug

Figure 2-1. Left side of engine, showing drain plugs

and charging receptacle.

Section Ill. CONTROLS AND INSTRUMENTS

2-5. General

2-6. Controls and Instruments

This section describes the various controls and

The controls necessary for operation of the centrifugal

instruments and provides the operator/crew with

pump are illustrated in figures 2-2 through 2-4 and are

sufficient information to assure proper operation of the

described in table 2-1.

centrifugal pump assembly.

2-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |