|

|||

|

|

|||

|

Page Title:

GENERAL DESCRIPTION |

|

||

| ||||||||||

|

|

GENERAL DESCRIPTION

Before placing a pump in service, unscrew the O i l

Chamber Plug (37) and fill the oil chamber in the Back

The Size 2.51 Pneumatic Centrifugal Pump is ideal for

Head (36) with the recommended oil.

general pumping work such as pumping out caissons,

cofferdams, tanks, bilges, sumps and trenches. They are

Squirt 15 or 20 drops of oil into the air inlet before

completely submersible and are designed to handle clear or

attaching the air hose.

dirty water, oil, sewage or moderately heavy sludge.

Reliable, trouble & free service is assured by pressurized

Unscrew the caps from the three Grease Fittings (3 and

lubrication of the impeller shaft seals, efficient closed-type

4 0 ) and insert the recommended grease with a

impeller, specially treated double water seals, powerful

Grease Gun. Two or three strokes of the Grease

governed multi-vane motor and protective air strainer. The

Gun is sufficient for the two Fittings nearest the air inlet.

Arbor is machined from stainless steel to prevent corrosion

The remaining fitting is the means of filling the chamber of

and the possible resultant rust bond between the Rotor and

the built-in grease lubricator. Insert grease until the

Arbor.

chamber is filled; a full chamber is indicated by Grease

The water Seals are suitable for liquids of temperatures

emerging from the Grease Level Valve (5). Be sure to

up to 210F.

replace the caps on the Fittings.

With the pump operating on 80 p.s.i. air pressure, the

actual water delivery through 50 ft. of 2" Fire Hose for

A " air hose, assembled with a No. UM75M Hose

various lifts is as follows: --

Coupling for connecting it to the pump, is recommended.

Use of smaller hose and fittings will restrict the air with

Delivery

Total Heed

subsequent loss in Pump efficiency.

feet

g.p.m.

260

10

Use of an air line oiler is recommened

240

20

for lubricating the pump motor.

225

30

the air line oiler as close to the tool

210

40

a s p o s s i b l e . Adjust

the

oiler

so

that

195

50

there is a slight mist

in

the

exhaust.

PREPARATION FOR USE

Larger capacity units may be

NOTE :

used, but do not use a unit having less

Recommended Lubricants

than 3/4" pipe tap inlet and outlet.

Grease, GAA; MIL-G-10924

Lubricating Oil,

Engine:

Grade

1,

MIL-L-21260

Specifications

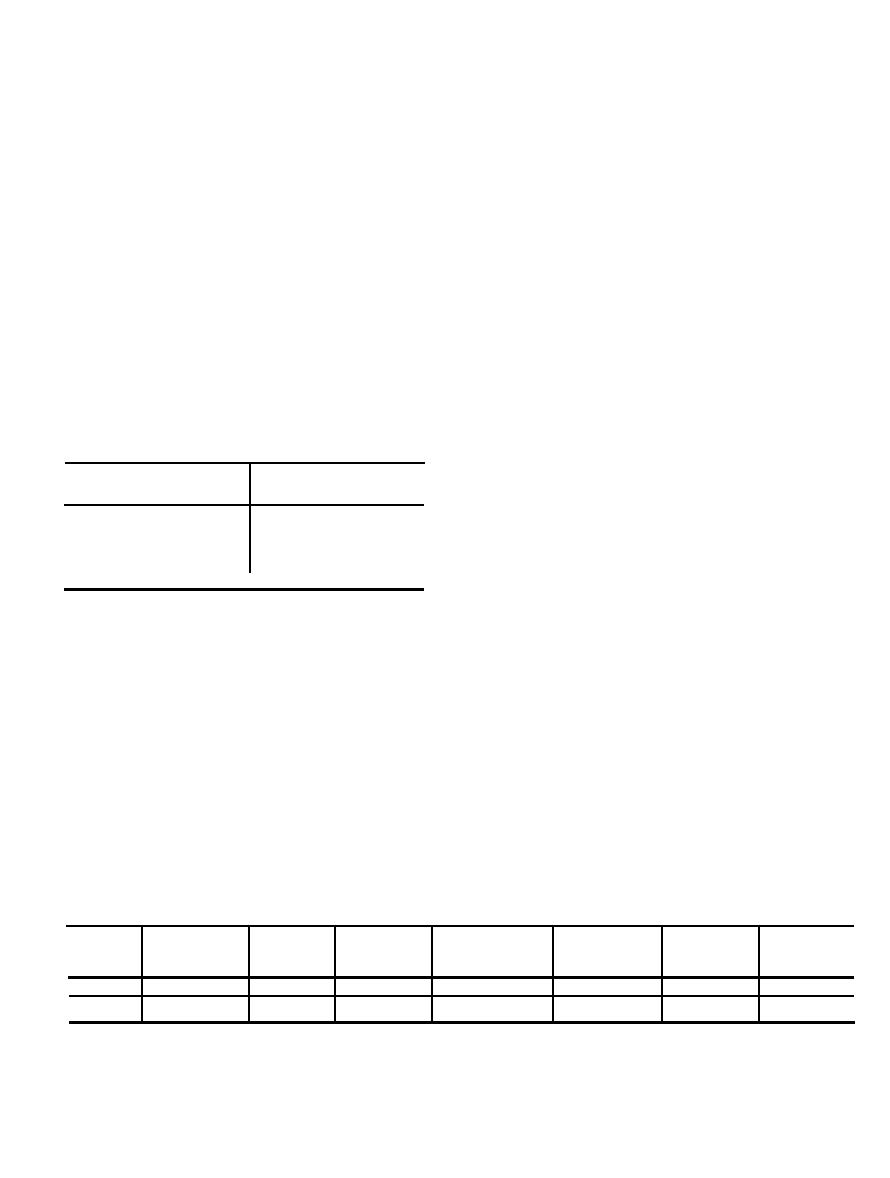

Size Opening

Size

Size

Height

Discharge

Discharge

Pump

Weight

Air Exhaust

Air Inlet

Pipe Tap

Pipe Tap

Will Enter

Pipe Tap

Hose

Hose

Inches

Inches

Inches

Inches

Inches

Inches

Lbs.

Inches

22

2

1

2

9x11

65-5/8

1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |